A zamanin yau, buƙatun abincin dabbobi ya ƙwace. A matsayin buƙatun kayayyakin dabbobi ke ƙaruwa, injinan abinci yana taka muhimmiyar rawa wajen biyan waɗannan buƙatun. Koyaya, Mills Ciyarwa sau da yawa fuskantar ƙalubalen riƙe da gyara zobe ya mutu, wanda muhimmin bangare ne na samar da murɗa mai inganci.

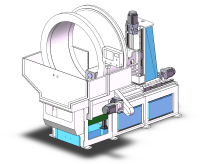

Don magance waɗannan matsalolin, ingantaccen bayani ya fito a cikin injin zirin zobe na atomatik. Wannan na'urar sabanin tana ba da cikakken aikin da aka tsara don zoben mutu gyaran cikin injin ciyarwa.

- share ramuka. Zai iya cire kayan saura a cikin zoben zobe. A tsawon lokaci, zobe zai mutu ko clogged, yana gabatar da tsarin samarwa. Da rami mai share, injiniyan maimaitawa na iya cire duk wani tarkace ko toshe a cikin zobe mutu ramuka. Wannan ba wai kawai inganta farashin samarwa na pellelet ba, amma kuma yana rage haɗarin wahala saboda yawan clogging.

- ramuka na chamfering. Hakanan yana da kyau kwarai a cikin rami chamfering. Chamfering shine tsari na nutsuwa da chamfering gefen rami a kan zobe mutu. Wannan fasalin yana kara ƙimar gabaɗaya da kuma lifspan na zobe mutu, suna ba da damar ciyar da injin don adanawa a lokacin musanyawa.

- nika saman ciki na zobe mutu. Wannan injin din na iya niƙa a cikin ciki na zobe mutu. Ta hanyar amfani da dabaru na rijiya, injin din na iya gyara duk wani abu na farfajiya ko lalacewa a zobe ya mutu. Wannan yana tabbatar da pellets ana samarwa tare da mafi girman daidai, inganta lafiyar abincin da kullun.