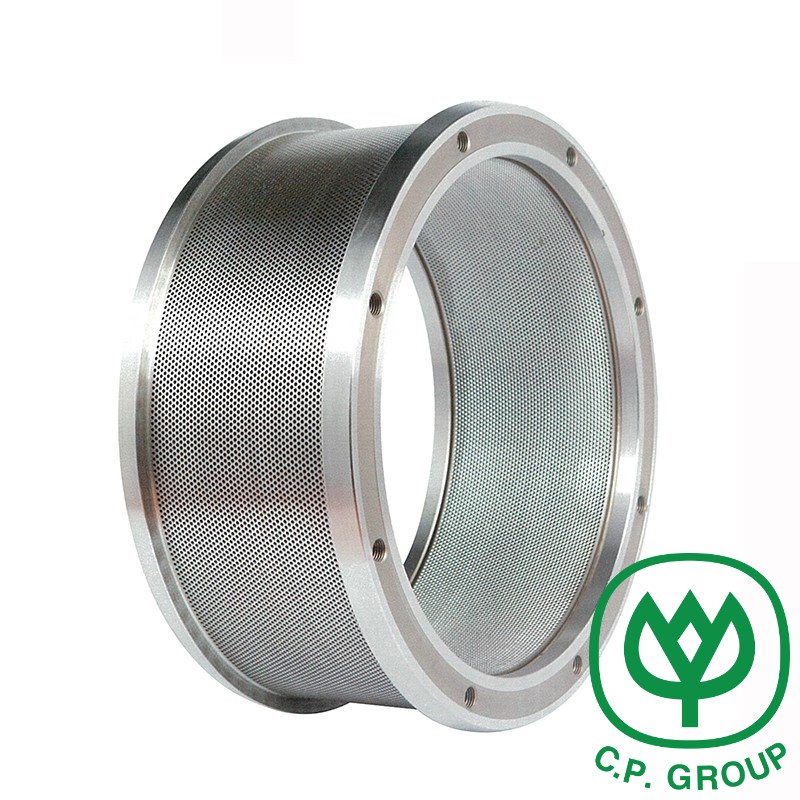

SZLH Jerin Pellet Mill Zobe ya mutu

- Shh.zhengyI

1.Ka kula da albarkatun kasa mai inganci, sakandare mai sakandare, billet bita;

2. Ackings ya mutu abu: x46cr13 / 4cr13 (bakin karfe), 42cmo / 20cmMo / 20coy karfe) ko wasu kayan al'ada) ko wasu kayan al'ada;

3. Matattarar bindiga da matattarar matalauta, tsararren matakai guda ɗaya, ƙoshin lafiya na ƙarshe, bayyanar abinci, bayyanar abinci, kyakkyawan bayyanar da babban fitarwa;

4.Sai hada hadadden murhu da ci gaba da quenching wutar lantarki don tabbatar da doguwar sabis na sabis;

5.Akraording ga kaifin da ake buƙata na abokin ciniki don tsara matakan matsakaiciya da ƙarfi;

Jarrabawar 6.CaMicmiscopic don tabbatar da ingancin samfurin;

42Crmo / 20crmnti Alloy Karfe Zobe Die Intern Fasahar:

Yankan → Dalidi → Minding → Minding → Mote → Carburizing → (Phoatsing) → Motar → Drinding → (Phoatsphorus Enting → (Phoatsphorus Enting → (Phoatsphorus Enbust → (Phoatsing) → Drinding → Drinding → (Phoatsphorus Enting → (Phoatsing) → Motar Antirust → Rigarthust → Riƙe → Duba Zaben;

X46CR13 / 4cr13 Bakin Karfe Zobe Die Interner:

Yankan → Mvening → Zagaye → Daidaitaccen → quenching → Plishing → Plifing Rami → Pliting Rami → Motsa Offper

| S / n | Abin ƙwatanci | Gimra Od * ID * Gabaɗaya Mataki * Pad -m | Girman rami mm |

| 1 | SZLH320 | 432 * 320 * 80 | 1-12 |

| 2 | Szlh350 | 500 * 350 * 180 * 100 | 1-12 |

| 3 | Szlh400 | 558 * 400 * 200 * 120 | 1-12 |

| 4 | Szlh400d | 558 * 400 * 218 * 138 | 1-12 |

| 5 | SZLH420 | 580 * 420 * 196 * 120 | 1-12 |

| 6 | SZLH420D | 580 * 420 * 140 | 1-12 |

| 7 | Szlh508 | 660 * 508 * 238 * 155 | 1-12 |

| 8 | Szlh508e | 660 * 508 * 284 * 185 | 1-12 |

| 9 | Szlh558 | 774 * 572 * 270 * 170 | 1-12 |

| 10 | Szlh578 | 774 * 572 * 300 * 200 | 1-12 |

| 11 | SZLH768 | 966 * 761 * 370 * 210 | 1-12 |

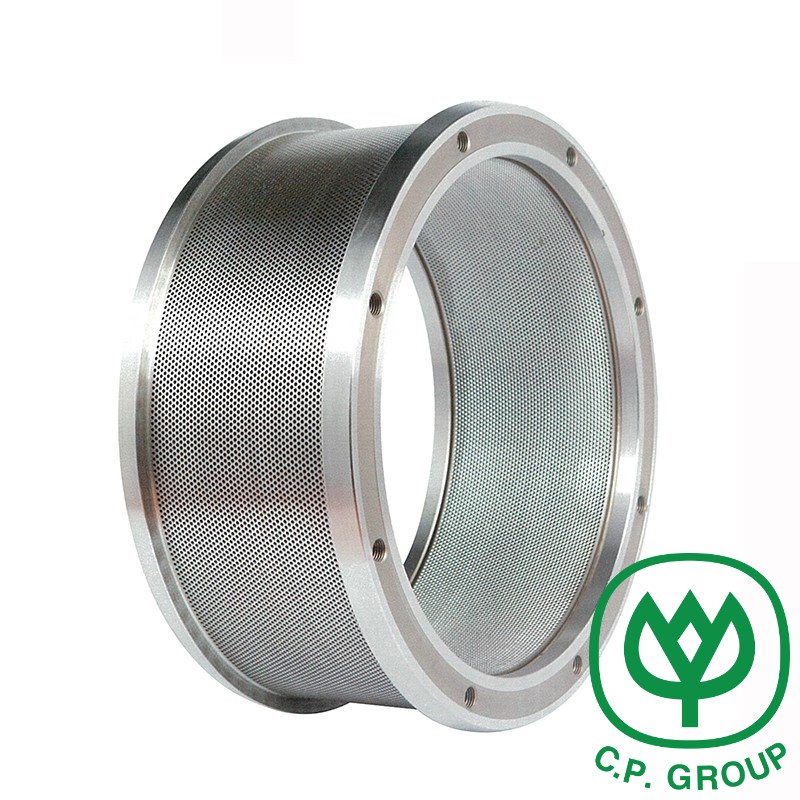

Take mai narkewa

Harami mai narkewa yana daya daga cikin manyan ayyukan aiki na pellet Mill. Amfani da shi don aiwatar da nau'ikan nau'ikan biofuel, abincin dabbobi da sauran murjiyoyi. Amfani da babban abin da ke faruwa-risticant siloy karfe (40cr, 20crmnti, GCR15), carburizing zafi magani, daidaituwa mai zafi. Rayuwar sabis tana da tsawo, kuma akwai nau'ikan nau'ikan halitta kamar su-dimbin hali ne ta hanyar dimbin siffa, toshe haƙoran haƙori, da kuma mai kama da rami. Ana yin ɓangaren matsakaicin ɓangaren rubutu na ciki da sauran sassan tare da daidaitattun abubuwan da mai amfani da kafawa na mai amfani.

Matakan kariya:

1. Daidai zaɓi zaɓi zaɓi wanda ya dace da rassi mai dacewa.

2. Daidai daidaita rata na aiki tsakanin zobe mutu kuma matsin lamba don kasancewa tsakanin 0.1 da kuma rumbarar roba ta zama a kan "kamar juyawa amma ba jujjuya" jihar);

3. Dole a yi amfani da sabon zoben zobe tare da sabon matsin lamba, da kuma matsin lamba da kuma zobe ya mutu dole ne a kwance kafin sannan ya karɓi. A lokacin da sasannin kafaffa suna bayyana a bangarorin biyu na matsin lamba, flante na matsin lamba a cikin lokaci don sauƙaƙe mai kyau dacewa a cikin lokaci don sauƙaƙe ya mutu;

4. Dole ne su sha tsaftacewa na farko da rabuwa da Magnetic kafin pelletzer don rage latsa baƙin ƙarfe cikin rami rami. Kuma don bincika rami na mutu rami don gani ko akwai wani toshe. Punch fita ko rawar da aka katange rami mai kauri a cikin lokaci;

5. A lokacin da gyaran, ya kamata a lura cewa mafi ƙarancin ɓangare na munanan ayyukan da ya mutu ya kamata ya zama ƙasa na matsa lamba bayan gyara, sai a sami damar gyara;

6. Harshen ruwa mai narkewa an yi shi ne da kayan sawa da kayan kwalliyar zinare da kuma magani mai zafi. Tsarin haƙoran haƙoran haƙoran na matsin lamba na harsashi yana da wani tasiri a kan aikin granias.

Profile da aka saba amfani da shi na kayan aikin haƙori: bayanan haƙori ta hanyar nau'in, bayanan mahalli ba ta hanyar ba, nau'in rami.

1. Pass da haƙoran mormers rollers ana amfani da galibi don pellezing dabbobi da kuma kaji. Amfanin wuce rollers shi ne cewa zobe mutu weyard a ko'ina, amma aikin cil ba shi da kyau.

2.Wana tsirar tsirar hakori na hakoran haƙora yana da kyakkyawan yanayin kayan aiki kuma ana amfani da shi a cikin masana'antu na abinci, amma sutturar zobe ta mutu ba ta da kyau. Kyakkyawan fasalin haƙoran haƙora mai matsin lamba tare da gefen sutturar ya dace da pletetizing na kayan maye. Slide a garesu.

Hukumar Hellical

Harami mai narkewa yana daya daga cikin manyan ayyukan aiki na pellet Mill. Amfani da shi don aiwatar da nau'ikan nau'ikan biofuel, abincin dabbobi da sauran murjiyoyi. Amfani da babban abin da ke faruwa-risticant siloy karfe (40cr, 20crmnti, GCR15), carburizing zafi magani, daidaituwa mai zafi. Rayuwar sabis tana da tsawo, kuma akwai nau'ikan nau'ikan halitta kamar su-dimbin hali ne ta hanyar dimbin siffa, toshe haƙoran haƙori, da kuma mai kama da rami. Ana yin ɓangaren matsakaicin ɓangaren rubutu na ciki da sauran sassan tare da daidaitattun abubuwan da mai amfani da kafawa na mai amfani.

Matakan kariya:

1. Daidai zaɓi zaɓi zaɓi wanda ya dace da rassi mai dacewa.

2. Daidai daidaita rata na aiki tsakanin zobe mutu kuma matsin lamba don kasancewa tsakanin 0.1 da kuma rumbarar roba ta zama a kan "kamar juyawa amma ba jujjuya" jihar);

3. Dole a yi amfani da sabon zoben zobe tare da sabon matsin lamba, da kuma matsin lamba da kuma zobe ya mutu dole ne a kwance kafin sannan ya karɓi. A lokacin da sasannin kafaffa suna bayyana a bangarorin biyu na matsin lamba, flante na matsin lamba a cikin lokaci don sauƙaƙe mai kyau dacewa a cikin lokaci don sauƙaƙe ya mutu;

4. Dole ne su sha tsaftacewa na farko da rabuwa da Magnetic kafin pelletzer don rage latsa baƙin ƙarfe cikin rami rami. Kuma don bincika rami na mutu rami don gani ko akwai wani toshe. Punch fita ko rawar da aka katange rami mai kauri a cikin lokaci;

5. A lokacin da gyaran, ya kamata a lura cewa mafi ƙarancin ɓangare na munanan ayyukan da ya mutu ya kamata ya zama ƙasa na matsa lamba bayan gyara, sai a sami damar gyara;

6. Harshen ruwa mai narkewa an yi shi ne da kayan sawa da kayan kwalliyar zinare da kuma magani mai zafi. Tsarin haƙoran haƙoran haƙoran na matsin lamba na harsashi yana da wani tasiri a kan aikin granias.

Profile da aka saba amfani da shi na kayan aikin haƙori: bayanan haƙori ta hanyar nau'in, bayanan mahalli ba ta hanyar ba, nau'in rami.

1. Pass da haƙoran mormers rollers ana amfani da galibi don pellezing dabbobi da kuma kaji. Amfanin wuce rollers shi ne cewa zobe mutu weyard a ko'ina, amma aikin cil ba shi da kyau.

2.Wana tsirar tsirar hakori na hakoran haƙora yana da kyakkyawan yanayin kayan aiki kuma ana amfani da shi a cikin masana'antu na abinci, amma sutturar zobe ta mutu ba ta da kyau. Kyakkyawan fasalin haƙoran haƙora mai matsin lamba tare da gefen sutturar ya dace da pletetizing na kayan maye. Slide a garesu.