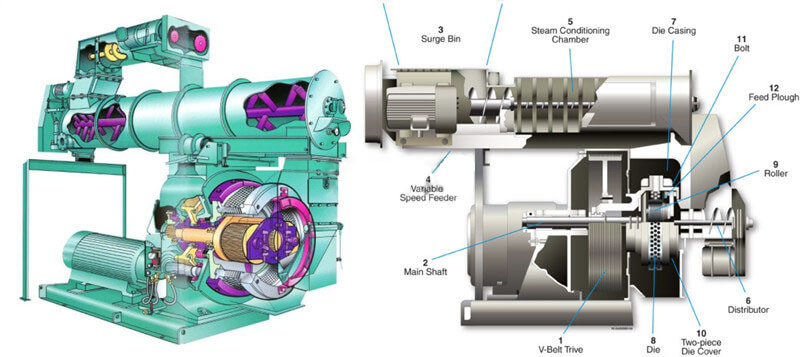

Hoop Rau Pellet Zeb Spare Xeem

- Shh.zhengyi

Peb tuaj yeem ua cov xovxwm tuag thiab cov zaub rau ntau yam ntawm ob qho tib si ntawm ob tog thiab txawv teb pellet zeb raws li kev kos duab thiab cov kev tsis sib xws. Xws li CPM, txheej txheem. tus lwm yam

Peb tseem muab lwm qhov, xws li cov iav, pinion, cov nplhaib tsis muaj qab hau, cov nplhaib sib dhos, txuas ntxiv rau cov menyuam yaus, cov kab ke

Lub Tshuab Cua Sov

1.Thov nqus dej degree, tsis muaj oxidation cov tshuaj tiv thaiv nyob rau hauv lub nplhaib tuag saum npoo, kom ua tau thawj smoothness ntawm tuag qhov sab hauv sab hauv.

2. Siv lub tshuab nqus tsev siab kawg nkaus, sib ntswg hauv qab thiab kev ntseeg siab ua kom muaj cua sov ua kom tsis txhob muaj kev tuag deformation.

3.CNC Cov Txheej Txheem Txheej Txheem, ua kom lub nplhaib tuag zoo ruaj khov.

4.With rationalally hloov kho cua sov, kev tiv thaiv cua sov thiab lub sijhawm txias thiab lub sijhawm txias, microstructure ntawm cov kev ua haujlwm zoo tshaj plaws.

5.Hog kom txias nrawm dua ua kom muaj kev faib tawm ntau dua carbide thiab kev ua haujlwm ntawm lub nplhaib tuag yog lav, ua rau sib npaug siv cov nplhaib tuag.

Ntau Lawm Flow