Cov tuag yog cov tseem ceeb tivthaiv nyob rau hauv pellet zeb. Thiab nws yog tus yuam sij rauUa PelletsCov. Raws li cov txheeb cais tsis tiav, tus nqi ntawm pellet zeb tuag poob nyiaj rau ntau tshaj 25% ntawm kev tswj hwm tus nqi ntawm tag nrho cov kev sib koom ua ke ntawm tag nrho cov kev cob qhia ntau lawm. Rau txhua feem pua taw tes nce nqi, koj kev sib tw ua lag luam poob qis los ntawm 0.25%. Yog li pellet mill specifications yog qhov tseem ceeb heev.

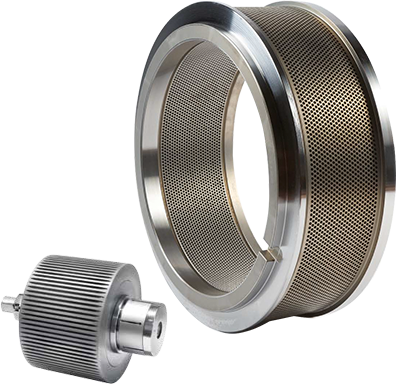

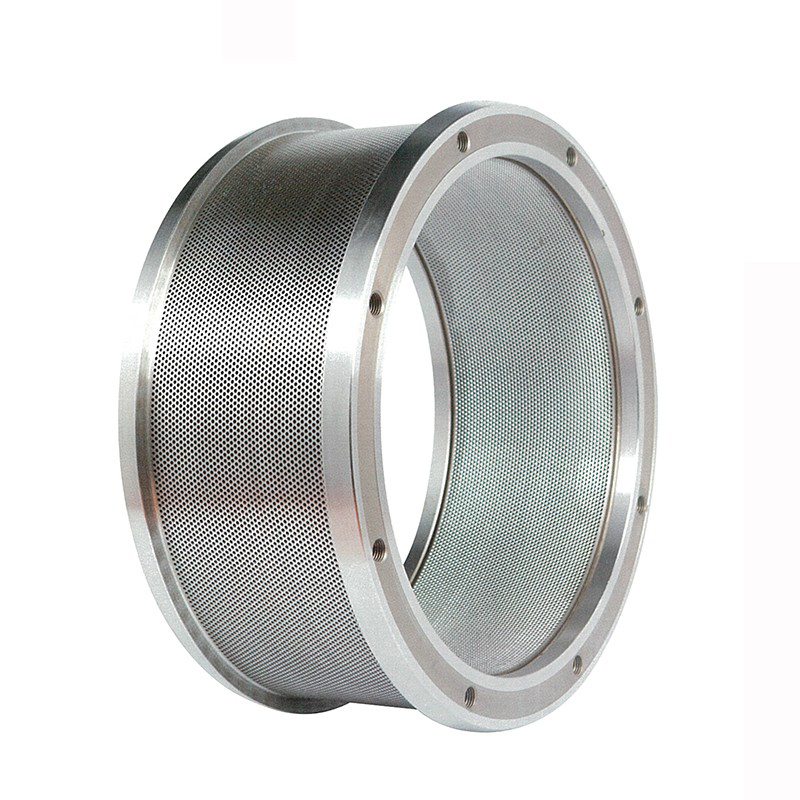

Shanghai Zhengyi (CPShzy) yog tus kws tshaj lijpub pellet zebTus xa khoom hauv Suav teb. Peb muab lub nplhaib tuag pellet zeb, pav ca tuag Pellet zeb thiab covPellet Zeb Xeem, xws li tiaj tus tuag, ntiv nplhaib tuag, pellet zeb cov menyuam, thiab lwm qhov rau cov pellet tshuab.

1.Pellet Zeb Tuag Khoom

Lub pellet zeb tuag feem ntau yog ua los ntawm cov hlau steel, alloy txheej txheem steel lossis stainless hlau los ntawm kev forging, thiab cov txheej txheem kho cua sov. Tus neeg siv tau xaiv raws li kev xeb ntawm cov khoom siv rawle. Cov khoom siv ntawm Pellet Zeb tuag yuav tsum yog ua los ntawm alloy qauv hlau los yog Stainless hlau Nplhaib Mould.

Cov hlau txheem txheem cov hlau txheem hlau, xws li 45 hlau, nws cov kev kho cua sov yog feem ntau 45-50 hrc, nws yog qhov tsis tshua muaj neeg tuag tsis zoo thiab tam sim no tau tshem tawm.

Allolo qauv txheej txheem hlau, xws li 40CR, 35Crmo, thiab lwm yam, nrog kev kho cua kub ua kom sov siab tshaj 50hrc thiab zoo sib xyaw cov khoom siv kho tshuab. Cov tuag ua los ntawm cov khoom siv siab thiab hnav tsis kam, tab sis qhov tsis zoo yog tias corrosion tsis zoo, tshwj xeeb tshaj yog rau ntses pub mis.

Tus nqi ntawm lub nplhaib tuag, uas yog ua los ntawm cov khoom siv, marigold pellets, cov ntoo ntoo, straw pellets, thiab lwm yam siab dua li cov hlau tsis muaj hlau. Ob qho tib si 20crmnti thiab 20mncr5 yog cov neeg muaj carrot-carrot-carrot, ob qho tib si yog tib yam, tshwj tsis yog tias cov hlau qub yog cov neeg suav tshiab. Txij li TI, ib qho tshuaj lom neeg, tsis tshua muaj muaj muaj muaj muaj muaj muaj 20crmn los ntawm Tuam Tshoj yog siv tsis pub dhau lub teb chaws Yelemees ntawm alloy txheej txheem hlau. Txawm li cas los xij, cov txheej hardened ntawm cov qauv hlau no tsuas yog txwv los ntawm lub carburizing txheej txheem rau qhov tob tshaj plaws ntawm 1.2 mm, uas yog qhov zoo dua tus nqi qis ntawm cov hlau no.

Cov ntaub ntawv hlau German suav nrog German stainless 4cr13, thiab lwm yam kev kho mob carburized, thiab kev ua kom muaj zog ua kom muaj zog carburized thiab ib txwm muaj zog ntau dua li carburized steels. Vim yog lub neej ntev ntawm cov stainless hlau tuag hlau, cov hloov zaus yog tsawg thiab yog li ntawd tus nqi per tankne yog tsawg.

Feem ntau, cov khoom tuag rau lub nplhaib tuag pellet zeb yog cov alloy txheej txheem hlau thiab stainless hlau cov ntaub ntawv.

2.Compression piv ntawm Pellet Zeb Tuag

i = d / l

T = l + m

M yog qhov tob ntawm cov neeg txo qis

Lub compression sib (i) yog qhov sib piv ntawm cov tuag lub qhov taub (d) thiab siv tau ntev (l) ntawm tuag.

Raws li qhov xwm txheej ntawm cov khoom siv raw, qhov sib piv tau xaiv cov khoom siv hluav taws xob, thiab cov tsos kom tsawg dua thiab qhov ntev yog qhov sib txawv, thiab tus hmoov tus nqi yog siab.

3.Tus nqi qhib ntawm lub nplhaib tuag

Tus nqi qhib ntawm Pellet Mill tuag yog qhov sib piv ntawm tag nrho thaj tsam ntawm lub qhov tuag mus rau qhov chaw zoo ntawm kev tuag. Feem ntau, siab dua tus nqi qhib ntawm kev tuag, qhov siab dua cov particle tawm los. Nyob rau hauv lub zeem muag ntawm kev ua kom muaj zog ntawm kev tuag, cov qhib tus nqi ntawm lub nplhaib tuag taus tuaj yeem txhim kho kom deb li deb tau.

Rau qee cov ntaub ntawv raw, raws li cov xwm txheej ntawm qhov tsim nyog compressional piv, yog li ntawd tias tus tuag dag zog tsis txaus, thiab qhov tshwm sim ntawm kev tawg tuag hauv kev tsim khoom. Nyob rau lub sijhawm no, cov tuab tuab ntawm lub nplhaib tuag yuav tsum tau nce nyob rau hauv lub preme ntawm ensuring ntev ntawm qhov ntev ntawm lub qhov tuag.

4.Txuam ntawm pellet zeb tuag thiab cov menyuam

Nws yog cov thev naus laus zis tseem ceeb tshaj plaws los txhim kho kev ua tau zoo ntawm granulation thiab ntev lub neej ntawm kev tuag. Nws yuav tsum muaj 4 yam:

- Lub nplhaib tshiab tuag nrog lub siab tshiab cov menyuam, zam kev siv ntau dhau ntawm kev siv ntawm lub siab.

- Raws li cov khoom siv ntawm cov ntaub ntawv, tshuab hom cov yam ntxwv ntawm kev xaiv ntau hom kev sib txawv, nyob rau hauv thiaj li yuav ua tiav qhov zoo tshaj plaws extrusion efficiency ntawm kev tuag thiab yob.

- Tus yuam sij rau Gap Fit yog ruaj khov thiab lub hauv paus ntsiab lus yog: tsis cuam tshuam rau lub peev xwm, sim so.

- Kev tswj kev pub mis ceev, kho qhov ntev thiab luv ntawm kev pub mis scraper kom tswj hwm txoj haujlwm, cov ntaub ntawv txheej faib.

5.Pellet Zeb Tuag Txheej Txheem Ua

Ntiv nplhaib tuag qhov yog qhov tsis tshua xav tau nyob rau hauv cov nqe lus ntawm kev ua thiab kev ua cov khoom siv hluav taws xob, thiab rau cov cuab yeej siv cua sov yog qhov yuav tsum tau los ua cov nplhaib ua kom zoo. Qhov zoo tshaj plaws lub tshuab cua sov muaj peev xwm txhim kho txoj kev nruj, tawv tawv, qaug zog ntawm cov hlau. Txawm li cas los xij, lub peev xwm los lav tau cov txheej hardness sib npaug rau txhua qhov tuag lub qhov yuav tsum tau ua qhov kev ua tau zoo thiab kev paub ntev.

6.Cov tuag saum npoo roughness ntawm sab hauv phab ntsa ntawm lub qhov tuag

Kev npau taws saum npoo av kuj yog qhov taw qhia tseem ceeb ntawm lub nplhaib tuag zoo. Feem ntau, tus nqi me me ntawm sab hauv phab ntsa saum npoo av saum npoo av yuav txhim kho qhov haum zoo, txo lub neej tuag, tab sis tus nqi ntawm kev ua lub nplhaib tuag yuav nce.

Ntiv nplhaib lub qhov ntxhib kuj cuam tshuam rau compression sib piv thiab sib sau ntawm cov hais, nrog rau kev ua haujlwm zoo. Nyob rau tib lub nplhaib tuag compression sib, cov nqi qis dua ntawm cov nplais ntoo, qhov zoo dua ntawm cov pellets ua thiab ntau dua cov khoom tsim ua tau zoo. Ntiv nplhaib zoo tuag yuav nce txog 0.8-1.6 microns, ntiv nplhaib tuag roughness yog li 0.8 microns, lub tshuab muaj tseeb ntawm cov khoom siv, tsis muaj kev sib tsoo.