1. Txawj ntse thiab automation: Ntiv qab pwm granulators zoo li kev qhia paub txog cov thev naus laus zis xws li siv lub tshuab ua tsis zoo thiab tsis siv neeg tswj cov algorithms. Cov neeg saib xyuas ntse tswj cov tshuab yuav tsum yog tus tsav tsheb tseem ceeb rau kev ua lag luam.

2. Kev tiv thaiv ib puag ncig thiab kev ceev xwm: Raws li lub ntiaj teb them ntau dua rau kev tiv thaiv ib puag ncig, ib puag ncig cov neeg granulators yuav tau nyiam dua. Qhov no suav nrog lub tshuab thev naus laus zis xws li siv lub zog txuas ntxiv mus tsav, txhim kho kev ua kom zoo dua qub thiab kev txhim kho cov khoom siv khib nyiab pov tseg pov tseg.

3. Tus kws khomob tsim kho customized: Cov kev xav tau ntau yam kev tsim kho kom haum thiab cov kev pab cuam uas yuav tsum tau ua raws li cov txheej txheem sib txawv.

4. Kev koom tes thoob ntiaj teb thiab nthuav dav kev ua lag luam, cov tuam txhab kev sib tw tuag thiab kev txhim kho thoob ntiaj teb kev sib tw thiab faib cov kev loj hlob.

5. Kev hloov pauv ntawm kev ua haujlwm siab thiab ruaj khov: los ntawm kev txhim kho cov khoom lag luam tuag, sib ntsib ntawm cov khoom sib txawv ntawm pellet roj kev tshwj xeeb thiab kev ua tau zoo hauv kev lag luam roj pellet. xav tau.

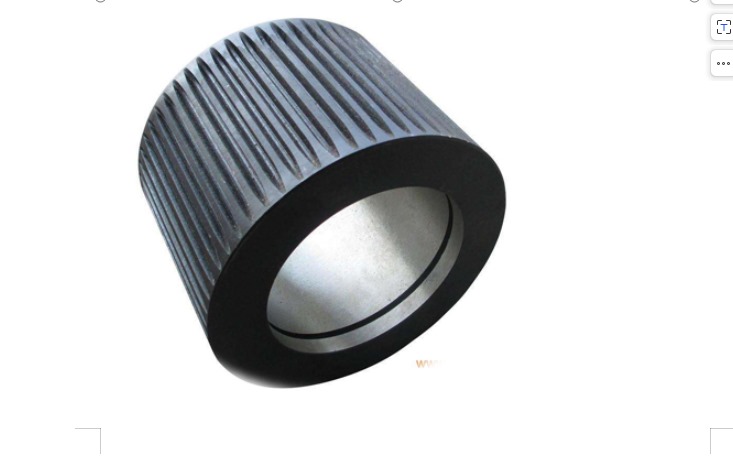

6. Kev tsim kho tshiab ntawm cov qauv ntsuas ruaj khov Nws ua kom zoo rau cov qauv ruaj ruaj ntawm lub nplhaib tuag kom ntseeg tau tias nws tuaj yeem siv rau hauv ntau daim ntawv thov. Kev ruaj khov thiab lub zog ntawm lub nplhaib pwm hauv kev siv cov ntawv thov.

7. Ntau zaus zaus cov kev cai ceev zaus thiab kev tswj hwm kub siab thiab muaj zog siv hluav taws xob ntau thiab muaj zog thaum lub zog kev lag luam, thiab kho cov txiaj ntsig kev lag luam ntau dua thaum ib puag ncig ntawm kev lag luam. Cov.

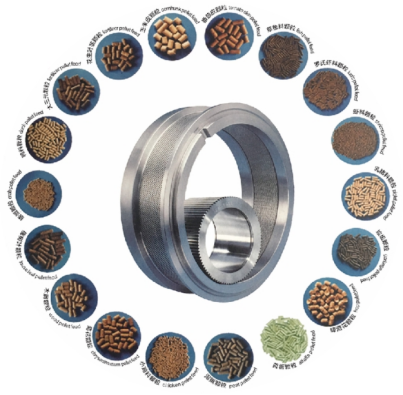

8. Versatility: Lub nplhaib-tuag Pellet tshuab yog haum rau pelletizing cov khoom sib txawv (sib xyaw ua ke, txhawb nqa cov peev txheej ntawm kev siv cov khib nyiab.

9. Txhim kho pwm tsim thiab cov xaiv: los ntawm kev xaiv pwm tsim thiab ua kom zoo nkauj thiab yoog tau zoo ntawm lub nplhaib tuag pellet tshuab yuav raug txhim kho pellet.

Cov kev hloov pauv thev naus laus zis tsis tsuas yog txhim kho kev ua haujlwm thiab kev txhim kho ntawm kev tiv thaiv ib puag ncig, ntsib kev ua lag luam kev ua lag luam, ib puag ncig phooj ywg, thiab cov cuab yeej siv customized, thiab cov cuab yeej siv customized.