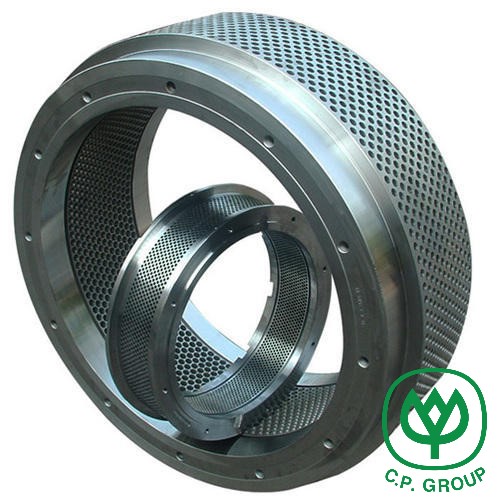

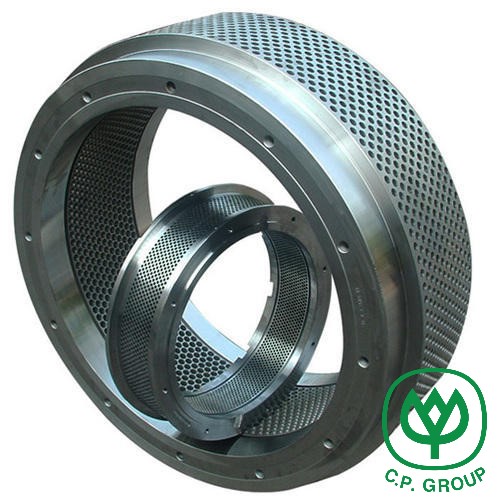

Zhengchang pellet Zeb nplhaib tuag

- Shh.zhengyi

1.Xaiv cov khoom siv raw khoom zoo, cov me me steedary, billassing billet;

2.Txhob cov khoom tuag: X46CR13 / 42cr13 (42Crmo / 20crmo / 20crmnti (Alloy Steel) lossis lwm cov ntaub ntawv kev cai;

3.Ibported phom laum laum thiab ntau-chaw nres tsheb laum, ib zaug ua tiav kev tuag lub qhov, siab tiav, kev tsim khoom zoo nkauj thiab muaj zis siab;

4.Xaiv Kev Ua Ke Ntawm Lub Tshuab Nqus Tsev thiab Nruam Cov Hluav Taws Xob kom ntseeg tau lub neej pabcuam ntev kev pabcuam kev ua haujlwm ntev;

5.acording rau lub hauv paus ntsiab lus thiab cov uas yuav tsum tau ntawm cov neeg siv khoom los tsim qauv kev sib piv thiab lub zog;

6.Microscopic kuaj kom ntseeg tau cov khoom lag luam zoo;

42CRMO / 20CRMNTI Alloy Steel Nplhaib Tuag Ua Tshuab:

Txiav → Forging → Roughing → Ro Tempering → Tempering → Tempering → LOJ Aximing (Phosidation Antir

X46CR13 / 4CR13 Stainless Hlau Nplhaib Tuag Ua Tshuab:

Txiav → Roughing → Rouging → Ua tiav → Drilling Qhov Kev Ntsuam Xyuas → Kev Ntsuam Xyuas → Kev Ntsuas Hluav Taws Xob → Rusty Roj Rusty → Xyuas thiab txuag kev xaiv;

| S / n | Tus qauv | Qhov loj me (hli) Od * id * tag nrho qhov dav * ncoo dav | Qhov luaj li cas mm |

| 1 | SZLH320 | 432 * 320 * 130 * 87 | 1-12 |

| 2 | SZLH350 | 500 * 350 * 180 * 100 | 1-12 |

| 3 | SZLH400 | 558 * 400 * 200 * 120 | 1-12 |

| 4 | SZLH400D | 558 * 400 * 218 * 138 | 1-12 |

| 5 | SZLH420 | 580 * 420 * 196 * 120 | 1-12 |

| 6 | SZLH420D | 580 * 420 * 214 * 140 | 1-12 |

| 7 | Szhlh508 | 660 * 508 * 238 * 155 | 1-12 |

| 8 | SzLh508E | 660 * 508 * 284 * 185 | 1-12 |

| 9 | SZLH558 | 774 * 572 * 270 * 170 | 1-12 |

| 10 | SZLH577 | 774 * 572 * 300 * 200 | 1-12 |

| 11 | SZLH768 | 966 * 761 * 370 * 210 | 1-12 |

Nqaim cov menyuam lub plhaub

Cov plhaub cov menyuam yog ib qho ntawm cov chaw ua haujlwm tseem ceeb ntawm pellet zeb. Siv los ua cov txheej txheem ntau yam biofuel pellets, tsiaj pub thiab lwm pellets. Siv cov kev hnav siab cov ris-resistant alloy steel (40Cr, 20cmnti, GCRR15), carburizing cua sov kev kho, tsis muaj zog hardness. Qhov kev pabcuam lub neej ntev, thiab muaj ntau hom qauv ntawm cov qauv xws li cov hniav-puab los ntawm-puab, hniav-puab thaiv, thiab qhov zoo li tus hniav. Cov nias cov menyuam ib feem yog ua los ntawm sab hauv Eccentric tus ncej thiab lwm qhov chaw nrog cov khoom siv sib npaug, thiab nws yog qhov yooj yim los hloov cov nias lub plhaub.

Cov kev ceev faj:

1. Kev xaiv xaiv qhov tsim nyog tuag compression;

2. Kho kom raug qhov sib txawv ntawm lub nplhaib tuag thiab cov neeg uas tau tsav los ntawm lub nplhaib 0.1 thiab 0.3mm (lub siab tshiab tau tig mus rau hauv ib qho "zoo li kev sib hloov tab sis tsis yog tig" xeev);

3. Lub nplhaib tshiab tuag yuav tsum tau siv nrog lub siab tshiab ntawm cov menyuam, thiab lub siab uas cov menyuam thiab lub nplhaib tuag yuav tsum xoob ua ntej thiab tom qab ntawd nruj. Thaum ntse cov ces kaum tshwm sim ntawm ob sab ntawm lub siab cov menyuam, lub flange ntawm lub siab grinder yuav tsum tau yooj yim rau lub sijhawm kom yooj yim ntawm lub siab thiab lub nplhaib tuag;

4. Cov khoom siv raw yuav tsum tau tu ua ntej thiab sib cais ua ntej lub pelletizer kom txo cov hlau nias rau hauv lub qhov tuag. Thiab txhawm rau tshuaj xyuas lub qhov tuag tsis tu ncua saib seb puas muaj kev thaiv. Punch tawm lossis tho tawm cov pob zeb ntawm cov pwm hauv lub sijhawm;

5. Yas deformation ntawm cov lus qhia lub khob raj ntawm lub nplhaib tuag yuav tsum tau kho. Thaum kho tau, nws yuav tsum tau sau tseg tias qis tshaj plaws ntawm kev ua haujlwm sab hauv lub taub hau, thiab tseem muaj cov khoom siv sab hauv

6. Lub Siab Cov Hluav Taws Xob Plhaub yog ua los ntawm cov khoom-resistant alloy khoom los ntawm kub ua thiab kho cua sov. Cov hniav nto ntawm lub siab cov khauj khaum muaj qee yam cuam tshuam ntawm kev ua haujlwm granulation.

Feem ntau siv cov menyuam lub plhaub profile profile: hniav profile los ntawm hom, cov hniav profile tsis los ntawm hom, qhov hom.

1. Dhau thiab Hniav Groove Rollers yog tsuas yog siv rau pelletizing tsiaj txhu thiab nqaij qaib cov ntaub ntawv. Qhov kom zoo dua ntawm cov rollers dhau los yog lub nplhaib tuag hnav tusyees, tab sis qhov kev ua tau zoo yog tsis zoo.

2.Qhov hniav zawj lub siab dua cov menyuam muaj cov khoom siv kom zoo, tab sis hnav ntawm lub nplhaib tuag tsis zoo li qub. Tus hniav zuaj puab siab cov menyuam nrog sealing ntug yog feem ntau haum rau lub pelletizing ntawm cov khoom siv dej. Xaub ntawm ob sab.

Helical cov menyuam plhaub

Cov plhaub cov menyuam yog ib qho ntawm cov chaw ua haujlwm tseem ceeb ntawm pellet zeb. Siv los ua cov txheej txheem ntau yam biofuel pellets, tsiaj pub thiab lwm pellets. Siv cov kev hnav siab cov ris-resistant alloy steel (40Cr, 20cmnti, GCRR15), carburizing cua sov kev kho, tsis muaj zog hardness. Qhov kev pabcuam lub neej ntev, thiab muaj ntau hom qauv ntawm cov qauv xws li cov hniav-puab los ntawm-puab, hniav-puab thaiv, thiab qhov zoo li tus hniav. Cov nias cov menyuam ib feem yog ua los ntawm sab hauv Eccentric tus ncej thiab lwm qhov chaw nrog cov khoom siv sib npaug, thiab nws yog qhov yooj yim los hloov cov nias lub plhaub.

Cov kev ceev faj:

1. Kev xaiv xaiv qhov tsim nyog tuag compression;

2. Kho kom raug qhov sib txawv ntawm lub nplhaib tuag thiab cov neeg uas tau tsav los ntawm lub nplhaib 0.1 thiab 0.3mm (lub siab tshiab tau tig mus rau hauv ib qho "zoo li kev sib hloov tab sis tsis yog tig" xeev);

3. Lub nplhaib tshiab tuag yuav tsum tau siv nrog lub siab tshiab ntawm cov menyuam, thiab lub siab uas cov menyuam thiab lub nplhaib tuag yuav tsum xoob ua ntej thiab tom qab ntawd nruj. Thaum ntse cov ces kaum tshwm sim ntawm ob sab ntawm lub siab cov menyuam, lub flange ntawm lub siab grinder yuav tsum tau yooj yim rau lub sijhawm kom yooj yim ntawm lub siab thiab lub nplhaib tuag;

4. Cov khoom siv raw yuav tsum tau tu ua ntej thiab sib cais ua ntej lub pelletizer kom txo cov hlau nias rau hauv lub qhov tuag. Thiab txhawm rau tshuaj xyuas lub qhov tuag tsis tu ncua saib seb puas muaj kev thaiv. Punch tawm lossis tho tawm cov pob zeb ntawm cov pwm hauv lub sijhawm;

5. Yas deformation ntawm cov lus qhia lub khob raj ntawm lub nplhaib tuag yuav tsum tau kho. Thaum kho tau, nws yuav tsum tau sau tseg tias qis tshaj plaws ntawm kev ua haujlwm sab hauv lub taub hau, thiab tseem muaj cov khoom siv sab hauv

6. Lub Siab Cov Hluav Taws Xob Plhaub yog ua los ntawm cov khoom-resistant alloy khoom los ntawm kub ua thiab kho cua sov. Cov hniav nto ntawm lub siab cov khauj khaum muaj qee yam cuam tshuam ntawm kev ua haujlwm granulation.

Feem ntau siv cov menyuam lub plhaub profile profile: hniav profile los ntawm hom, cov hniav profile tsis los ntawm hom, qhov hom.

1. Dhau thiab Hniav Groove Rollers yog tsuas yog siv rau pelletizing tsiaj txhu thiab nqaij qaib cov ntaub ntawv. Qhov kom zoo dua ntawm cov rollers dhau los yog lub nplhaib tuag hnav tusyees, tab sis qhov kev ua tau zoo yog tsis zoo.

2.Qhov hniav zawj lub siab dua cov menyuam muaj cov khoom siv kom zoo, tab sis hnav ntawm lub nplhaib tuag tsis zoo li qub. Tus hniav zuaj puab siab cov menyuam nrog sealing ntug yog feem ntau haum rau lub pelletizing ntawm cov khoom siv dej. Xaub ntawm ob sab.