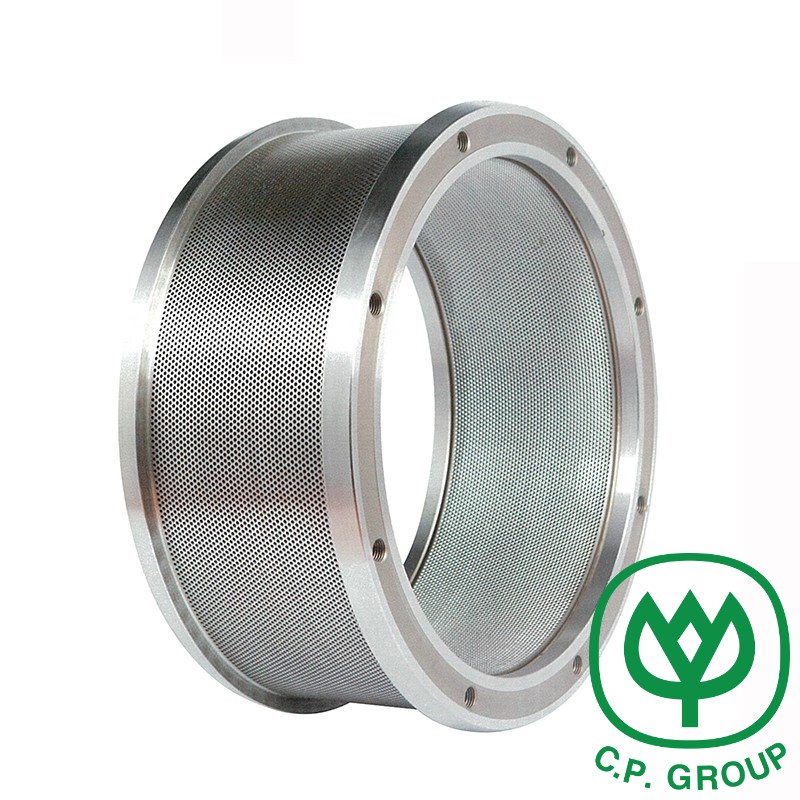

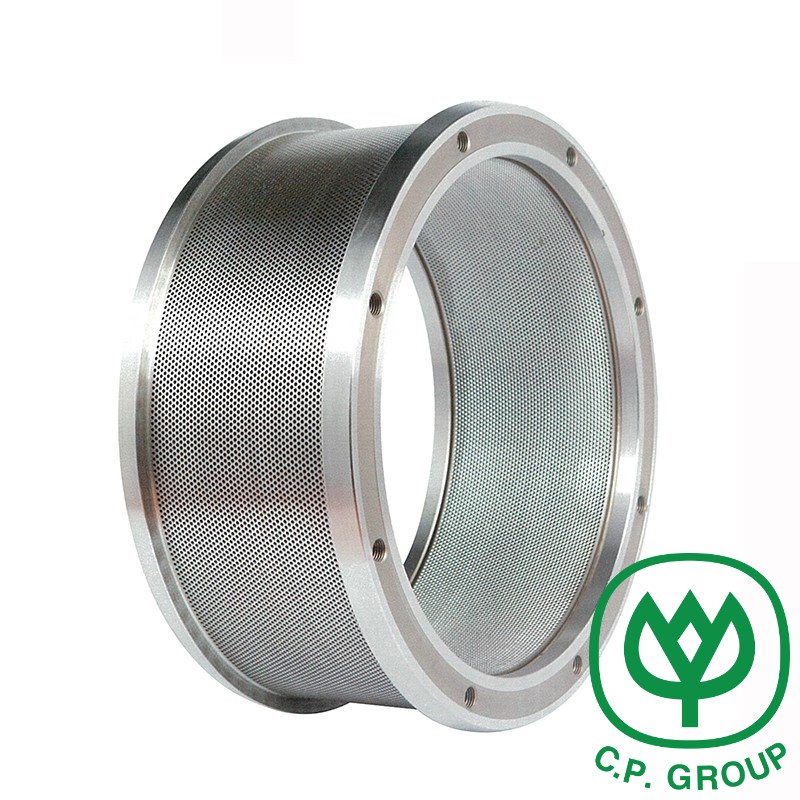

SZLH Series Pellet Millet Mill Mhete Ife

- Shhi.zhengyi

1.Select yakakwirira-mhando zvigadzirwa zvemhando yepamusoro, Sekondari steelmaking, Dhighiya Billet;

2.Kutora kufa zvinhu: x46cr13 / 4CC13 (Stainless Simbi), 42crmo / 20crrrnnti (Alloy Steel) kana zvimwe zvinhu zvetsika;

3.Reported Gun Drill uye Multi-Station Drill, imwe-nguva yekugadzira kufa gomba, yakakwira-yemhando yekupedzisa, kugadzirwa kwekudya, kutaridzika kwakanaka uye kwakakwirira kubuda;

4.Select iyo musanganiswa weva vaCuum

5.accord kusvika iyo nheyo uye zvinodiwa zvemutengi kuti zvigadziriswe kumanikidza uye simba;

6.microscopic yekuongorora kuti ive nechokwadi chechigadzirwa mhando;

42crmo / 20crmnnti Alloy Steel Mhete Die Kugadzirisa Tekinoroji:

Kucheka → Kugara → Kugadzirisa → Kuenderera

X46CR31 / 4CR313 Stainless Steel Mhete Die Kugadzirisa Tekinoroji:

Kucheka → kukanganisika → Kuenderera → Kugadzirisa

| S / n | Modhi | Saizi Od * ID * yakazara upamhi * Pad Worth -m | Gomba saizi mm |

| 1 | SZLH320 | 432 * 320 * 130 * 87 | 1-12 |

| 2 | SZLH350 | 500 * 300 * 180 * 100 | 1-12 |

| 3 | SZLH400 | 558 * 400 * 200 * 120 | 1-12 |

| 4 | SZLH400D | 558 * 400 * 218 * 138 | 1-12 |

| 5 | SZLH420 | 580 * 420 * 196 * 120 | 1-12 |

| 6 | SZLH420d | 580 * 420 * 214 * 140 | 1-12 |

| 7 | SZLH508 | 660 * 508 * 238 * 155 | 1-12 |

| 8 | SZLH508E | 660 * 508 * 284 * 185 | 1-12 |

| 9 | SZLH558 | 774 * 572 * 270 * 170 | 1-12 |

| 10 | SZLH578 | 774 * 572 * 300 * 200 | 1-12 |

| 11 | Szlh768 | 966 * 761 * 310 * 210 | 1-12 |

Yakakwira roller shell

Iyo roller shell ndeimwe yenzvimbo huru dzekushanda dzePellet Chillet. Yaishandiswa kuitisa akasiyana-siyana biofuel pellets, chikafu chemhuka uye mamwe mapepa. Uchishandisa yakakwira-yakanyanya-inodzivirira alloy simbi (40cr, 20crbnti, gcr15), carbluzzing kupisa kurapwa, kuomarara kwakatarwa. Hupenyu hwebasa hwakareba, uye kune dzakasiyana mhando dzezvimiro zvakaita sezino-rakaumbwa-rakaumbwa, rakaumbwa, rakaumbwa-mazino akavharika, uye gomba rakaumbwa. Iyo yekudzvinyirira roller chikamu yakagadzirwa neyenccentric shaft uye zvimwe zvakanakira kuenderana neyekudzvanywa zvinodikanwa zveMushandisi, uye zviri nyore kupeta uye kuisa, uye zviri nyore kutsiva kudzvanywa roller shell.

Zvekungwaririra:

1. Zvakanyatso sarudza yakakodzera kufa gomba rekumanikidza ratio;

2..

3 Kana makona akapinza anoonekwa pamativi ese eanomanikidza roller, flange of Prontoon roller inofanira kunyorwa neganda rekunyepedzera panguva yekufambisa yakakodzera pakati pekumanikidza.

4 Uye kutarisa gomba rekufa nguva nenguva kuti uone kana paine chero bhuroka. Punch kunze kana kudhiraira kunze kweiyo yakavharika mbichana gomba munguva;

5. Kushatisa kwepurasitiki kweiyo gwara rekufambisa koni yemhete kufa kunofanirwa kugadziriswa. Kana uchigadzirisazve, zvinofanirwa kucherechedzwa kuti chikamu chakadzika kwazvo chemukati chemukati chemhete chinofanira kunge chiri chechiitiko cheCoccentric Shaller mushure mekugadzirisa neimwe nzira, mhete dzinofa dzinofanira kutapurwa;

6. Iyo yekumanikidza roller shell yakagadzirwa neyekupfeka-inodzivirira elloy zvinyorwa negoridhe kugadzirisa uye kupisa kurapwa. Iyo zino sosi yemafomu eiyo yekumanikidza roller shell ine imwe pesvedzero pakubata kwekuita.

Kazhinji inoshandiswa roller shell tooth profile

1. Pfuura uye mazino Groove Rollers anonyanya kushandiswa kune pelletizing lipstock uye poultry zvinhu. Kubodzwa kwePass ROLLES ndeyekuti mhete inofa yakachena, asi iyo coil performance ndeye murombo.

2.Hwekuti mazino Groove chimiro kumanikidza roller ane yakanaka coil yekuita basa uye inowanzo shandiswa mufekitori rekudya, asi kupfeka kwemhete kufa hakuna yunifomu. Iyo zino groove chimiro kumanikidza roller ine chisimbiso chinonyanya kukodzera kune iyo pelletizing yezvinyorwa zvemumvura. Kutsvedza pamativi ese maviri.

Helical roller shell

Iyo roller shell ndeimwe yenzvimbo huru dzekushanda dzePellet Chillet. Yaishandiswa kuitisa akasiyana-siyana biofuel pellets, chikafu chemhuka uye mamwe mapepa. Uchishandisa yakakwira-yakanyanya-inodzivirira alloy simbi (40cr, 20crbnti, gcr15), carbluzzing kupisa kurapwa, kuomarara kwakatarwa. Hupenyu hwebasa hwakareba, uye kune dzakasiyana mhando dzezvimiro zvakaita sezino-rakaumbwa-rakaumbwa, rakaumbwa, rakaumbwa-mazino akavharika, uye gomba rakaumbwa. Iyo yekudzvinyirira roller chikamu yakagadzirwa neyenccentric shaft uye zvimwe zvakanakira kuenderana neyekudzvanywa zvinodikanwa zveMushandisi, uye zviri nyore kupeta uye kuisa, uye zviri nyore kutsiva kudzvanywa roller shell.

Zvekungwaririra:

1. Zvakanyatso sarudza yakakodzera kufa gomba rekumanikidza ratio;

2..

3 Kana makona akapinza anoonekwa pamativi ese eanomanikidza roller, flange of Prontoon roller inofanira kunyorwa neganda rekunyepedzera panguva yekufambisa yakakodzera pakati pekumanikidza.

4 Uye kutarisa gomba rekufa nguva nenguva kuti uone kana paine chero bhuroka. Punch kunze kana kudhiraira kunze kweiyo yakavharika mbichana gomba munguva;

5. Kushatisa kwepurasitiki kweiyo gwara rekufambisa koni yemhete kufa kunofanirwa kugadziriswa. Kana uchigadzirisazve, zvinofanirwa kucherechedzwa kuti chikamu chakadzika kwazvo chemukati chemukati chemhete chinofanira kunge chiri chechiitiko cheCoccentric Shaller mushure mekugadzirisa neimwe nzira, mhete dzinofa dzinofanira kutapurwa;

6. Iyo yekumanikidza roller shell yakagadzirwa neyekupfeka-inodzivirira elloy zvinyorwa negoridhe kugadzirisa uye kupisa kurapwa. Iyo zino sosi yemafomu eiyo yekumanikidza roller shell ine imwe pesvedzero pakubata kwekuita.

Kazhinji inoshandiswa roller shell tooth profile

1. Pfuura uye mazino Groove Rollers anonyanya kushandiswa kune pelletizing lipstock uye poultry zvinhu. Kubodzwa kwePass ROLLES ndeyekuti mhete inofa yakachena, asi iyo coil performance ndeye murombo.

2.Hwekuti mazino Groove chimiro kumanikidza roller ane yakanaka coil yekuita basa uye inowanzo shandiswa mufekitori rekudya, asi kupfeka kwemhete kufa hakuna yunifomu. Iyo zino groove chimiro kumanikidza roller ine chisimbiso chinonyanya kukodzera kune iyo pelletizing yezvinyorwa zvemumvura. Kutsvedza pamativi ese maviri.