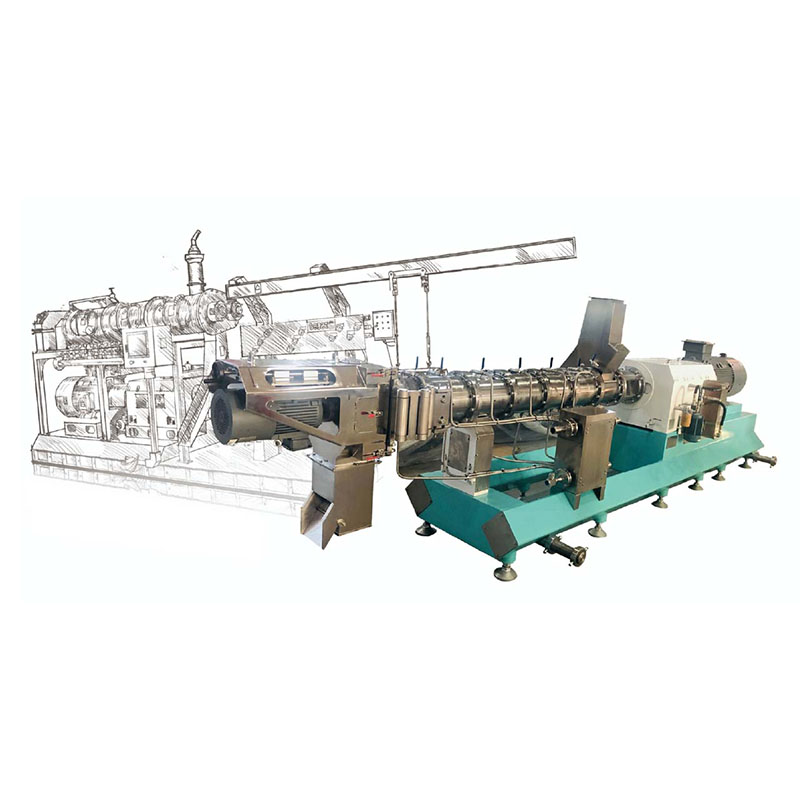

Moetsi oa litsebi Twin Screwer

- Shh.zhengyi

Tlhaloso ea Sehlahisoa

Lipontšo tse fapaneng tsa lits'ebetso, joalo ka ha ho ka hlahisa lipalesa, butle-butle, u tlose (shrinks (shrimp fepa, tfins fepa, jj.)Pherekano ea sebopeho sa mantlha, ka motsoako oa likarolo tse fapaneng tsa lefutso, li ka kopana le tlhahiso eaLisebelisoa tse fapaneng tsa foromo.

Mokhatlo o tsoang phahameng, lebokoseng la lihlahisoa tsa likere, le kenng letsoho, le behelletsoeng ka senngoang, sensor ea meralo ea letsoho,bophelo bo bolelele ba tšebeletso.

Tsamaiso ea taolo ea Litonki e ka khethoa ho laola letlotlo la thepa ka botšepehi.

PUSELETSO EA PUSELETSO le tšitiso e ntle, li khona ho bona mocheso, khatello le liparame tse ling inthaneteng.

Bakeng sa ho fepa mochini o mo phehellang ho sebetsa le boiler, boiler, ka mehla e ka hlahisa mouoane o fetisitsoeng ke lihlapi. Mochini o ka hlahisa boholo bo fapaneng a li-pellets, ho tloha ho 0.9mm-1.5mm, bakeng sa tlhapi, lihlahla, makhala, makhala, masela.

Mochine ona o amohela li-Steam tse tsoang 'me o na le bokhoni bo boholo le boleng bo boholo. Ke khetho e phethahetseng bakeng sa mapolasi a mahareng le e kholo ea menoana kapa litlhapi fepa li-pellets tse sebetsang limela. Re boetse re sebelisa mochini ona ho mola oa lihlapi tse metsi, ka kopo sheba mochini ona hodima moleng oa tlhahiso.

Ts'ebetso ea lisebelisoa

1. Bokhoni bo phahameng le tšebeliso e tlase, lisebelisoa tsa phofo li ka sebetsoa ho ntlafatsa boleng ba pellet le katleho.

2. Tsoela pele tsamaiso ea khafetsa, ka tsamaiso ena, e ka hlahisa li-pellets tse fapaneng ka ho fetola lebelo.

3. Ho na le mefuta e 4 ea hlobo e kopana le litlhokahalo tsohle tse lekanang. Li nkuoa habonolo le ho fetoha.

4. Rekhoebo eo e amana le boiler, thepa e ka ba e tsamaeang pele, ka hona boleng le katleho ea li-pellets ha li etsoe.

Mesebetsi e tsitsitseng, e ka sebetsa ho tsoelang pele.

Metsi a metsi a fepa mochini oa ho sebetsa mochini

Ho tloha ka tikoloho ea liphallelo tsa ExptS ke khatello e phahameng le mocheso o phahameng, ka hona setempe se tla fetoha serikhoe, 'me protheine e tla tlosoa. Sena se tla ntlafatsa tsitsipano ea metsi le ho ba le semelo. Ka nako e ts'oanang, Salmonella e leng libaktheria tse ling tse kotsi li bolaoa tšebetsong ena. Ha boitsebiso boo bo tsoa ho batho bohle, khatello e tla fela ka tšohanyetso, ebe e theha li-pellets. Sesebelisoa se sehiloeng ka har'a mochini o tla khaola li-pellets ka bolelele bo hlokahalang.

Paramente

| Mofuta | Matla (kw) | Tlhahiso (T / h) |

| Tse95 | 90/110/132 | 3-5 |

| Tse128 | 160/185/200 | 5-8 |

| Tse1488 | 250/315/450 | 10-15 |

Likarolo tsa ho senyeha