Inkonzo yobomi bomsesane oswelekileyo iya kuchaphazeleka zizinto ezininzi, kubandakanya nezinto ezibonakalayo zeringi, iimpawu zezixhobo zokuvelisa, iindlela zokusebenza kunye nokugcinwa kobomi. Nangona kunjalo, ngokugcinwa okufanelekileyo nokusebenzisa, inkonzo yobomi bokufa ngeseti inokwandiswa ngokufanelekileyo.

Ubomi buBantu ngokubanzi beGranulator i-granulator ifa.

Ngapha koko, inkonzo yobomi bomsesa wokufa komndatha onokuthi ufikelele kwi-1000 ukuya kwi-1400 yeeyure.

-Ukulungiswa okuhle kunye nokukhathalela, ubomi benkonzo ye-fash banokuthi bandiswe.

Izinto ezichaphazela ubomi bomsesane wasweleka kwi-granuetor

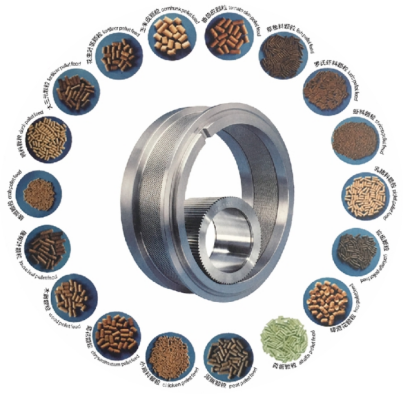

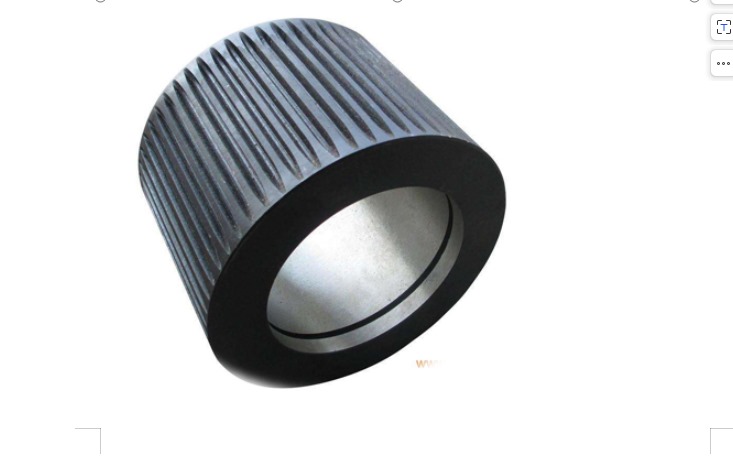

- ** Izinto ezibonakalayo Umzekelo, iringi yentsimbi engenasimo ingenayo ngokubanzi inobomi benkonzo ende, ngelixa i-carbon ye-carbon yensimbi inesifo se-ring inobomi obufutshane.

- ** Izixhobo zemveliso **: Izixhobo ezahlukeneyo zineedigri ezahlukeneyo zokunxiba. Izinto ezinobunzima obuphezulu okanye umxholo ophezulu wefibre unokukhawulezisa ukunxila komsesa.

- ** Indlela yokusebenza **: Indlela yokusebenza ngokuchanekileyo kunye nesondlo sisitshixo sokwandisa ubomi bomsesa. Oku kubandakanya ukucoca iringi kufa rhoqo, ukugcina ukuthambisa ngokufanelekileyo, nokuthintela ukulayisha ngaphezulu.

Iindlela zokwandisa ubomi bomhadi oswelekileyo

-Khetha izixhobo zokufa kukhala ngomgangatho ophezulu kwaye zilungele iimfuno zemveliso.

-Ukuqhuba ukusebenza kunye nokugcinwa ngokungqongqo ngokungqinelana neenkqubo zokusebenza kunye nencwadana yokulungisa.

-Ukujonga rhoqo ukunxila kuyafa nokutshintsha i-ring enesantya esinxilisayo ngendlela yexesha elifanelekileyo.

-Sebenzisa i-hubring efanelekileyo yokugcina ioyile elungileyo yokufa.

Ngale ndlela ingentla, ubomi benkonzo yokufa kweringi banokuthi bandiswe ngokufanelekileyo, iindleko zemveliso zinokuncitshiswa, kwaye ukuvelisa iinkonzo zinokuphuculwa.