Zhengchang Pellet Golling Fiya

- Shh.zhengyi

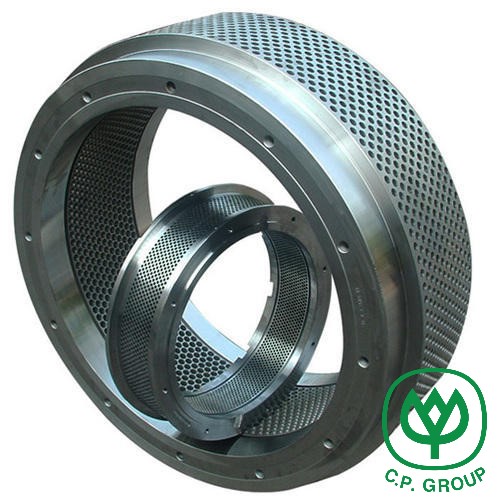

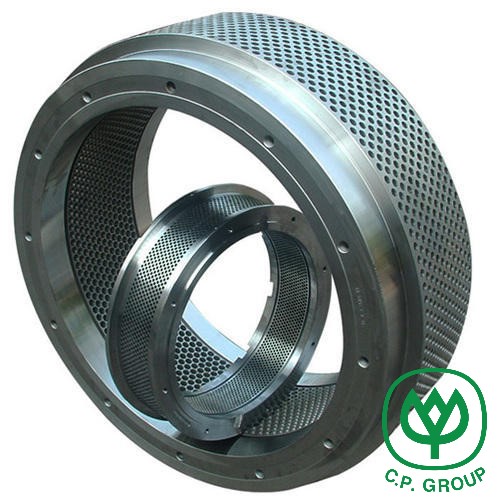

1.Khetha izixhobo ezikumgangatho ophezulu, i-Steeling Steelings, i-billess billet;

Ukufumana izinto zokufa: I-X46ccr13 / 4cr13 (intsimbi engenasitali), i-பALCRO / 20CMTIN / 20CMTIN (intsimbi) okanye enye into eyisiko;

3.Imported gun drill and multi-station drill, one-time forming die hole, high-quality finish, production of feed, beautiful appearance and high output;

4.Khetha indibaniselwano yezixhobo ze-vacuum kunye nezixhobo eziqhubekayo zokuqinisekisa ukuthanda izinto ezinde;

5.Accodung kumgaqo kunye neemfuno zomthengi kuyeyila umlinganiso woxinzelelo kunye namandla;

Uvavanyo lwe-6.imicroscopic ukuqinisekisa umgangatho wemveliso;

I-HoulCom / 20cROTROALD STEEL SETY Iteknoloji yokuqhuba:

Ukusika → Ukutolika

I-X46ccct13 / 4cr13 yensimbi ye-Stainess yensimbi yokuqhuba:

Ukusika → Ukutolika

| S / n | Imodeli | Ubungakanani (mm) I-OD * i-ID * iyonke yobubanzi | Ubungakanani beHole mm |

| 1 | Szlh320 | 432 * 320 * 130 * 87 | 1-12 |

| 2 | Szlh350 | I-500 * 3550 * 180 * 100 | 1-12 |

| 3 | Szlh400 | I-558 * 400 * 200 * 120 | 1-12 |

| 4 | Szlh400d | I-558 * 400 * 218 * 138 | 1-12 |

| 5 | Szlh420 | I-580 * 420 * 196 * 120 | 1-12 |

| 6 | Szlh420d | I-580 * 420 * 214 * 140 | 1-12 |

| 7 | Szlh508 | I-660 * 508 * 238 * 155 | 1-12 |

| 8 | Szlh508e | I-660 * 508 * 284 * 185 | 1-12 |

| 9 | Szlh558 | 774 * 572 * 270 * 170 | 1-12 |

| 10 | Szlh578 | 774 * 572 * 300 * 200 | 1-12 |

| 11 | Szlh768 | I-966 * 761 * 370 * 210 | 1-12 |

I-roller ye-roller ye-roller

I-roller iqokobhe yenye yeenxalenye eziphambili zokusebenza kwe-pellet yezigidi. Isetyenziselwe ukuqhubela phambili i-pellets ezahlukeneyo ze-biofuel, ukutya kwezilwanyana kunye nezinye iipelethi. Sebenzisa intsimbi ephezulu yokunganyangeki (i-40ccr, 20crmnti, i-GCR15), ukucinga ubushushu obushushu, ubunzima obufanayo. Ubomi benkonzo bude, kwaye kukho iintlobo ezahlukeneyo zezakhiwo ezifana ne-tooth-imile ivinjwe ivalwe, kwaye ivinjwe izinyo, kunye nomngxunya. Inxalenye ye-roller ye-roller yenziwa nge-shall yangaphakathi ye-eccentric kunye nezinye iindawo ezinemilinganiselo echanekileyo, elungele ukulungisa umgama phakathi kweemfuno zokuvelisa umsebenzisi, kwaye kulula ukulungisa i-roller ye-roller yeqokobhe.

Ukulumkela:

1. Ngokuchanekileyo khetha umlinganiso ofanelekileyo wokucinezelwa kweHie Hole;

2. Ngokuchanekileyo ihlengahlengise umsantsa ophakathi phakathi kwensingi kwaye uxinzelelo luphakathi lube phakathi kwe-0.1 kunye ne-0.3mm (i-roller yoxinzelelo iqhutywa emva kokuba i-granulator ivuliwe emva kokuba i-Granulator ivuliwe;

I-3. I-ring entsha ifa kufuneka isetyenziswe nge-roller yoxinzelelo entsha, kwaye uxinzelelo lroller kunye ne-roller kufuneka ikhululwe ngaphambili kwaye iqiniswe. Xa iikona ezibukhali zivela kumacala omabini e-roller, iflethi ye-roller yoxinzelelo kufuneka ibe yimgqomo yesandla ngexesha lokuqhubela phambili i-roller elungileyo kwaye i-fasa ifa;

I-4. Izinto ezingafunekiyo kufuneka ziphinde zicoceke ngokutsha ukucoca kunye nokwahlulahlula i-magnetic phambi kwepelletitizer ukunciphisa i-iron ecinezela ukuya kumngxunya wokufa. Kunye nokutshekisha umngxunya wokufa rhoqo ukuze ubone ukuba ikhona na ibhloko. Punch ngaphandle okanye uqhube ngaphandle umngxunya ovaliweyo ngexesha;

I-5. Ukuphuhliswa kweplastiki yomngxunya wengqengqelo yengqengqelo yekhonkco kufuneka kulungiswe. Xa ilungisa, kufuneka iqatshelwe ukuba eyona ndawo iphantsi yomphezulu wangaphakathi wokufa kwesandi kufuneka ibe yi-2mm ngaphezulu kwe-occentric groove roove roove roove roove roove roove roove;

I-6. I-roller ye-roller ye-roller yenziwa ngezinto ezinokunyangeka i-alting yeGolide ngokuPhakanyiswa kweGolide kunye nonyango lobushushu. Indlela yokungaphezulu kwamazinyo ye-roller ye-roller ineempembelelo ezithile kumsebenzi wokusebenza.

Iprofayile esetyenziswayo esetyenziswayo iprofayile ye-roller ye-roller

I-1. Dlula kunye neeRoove zamazinyo zisetyenziselwa ikakhulu ekuthatheni imfuyo kunye nempahla yeenkukhu. Inzuzo yokupasa i-rollers kukuba i-ring idle ngokulinganayo, kodwa ukusebenza kwekhoyini kulihlwempu.

2.Izinyo le-Groove Groove i-rooller iroller inomsebenzi ofanelekileyo wokusebenza kwaye isetyenziswa kwimithombo yobisi, kodwa ukunxibiswa kwe-farting ayifani. Izinyo le-Groove I-Groove i-Groove i-roller enomda otywinelweyo ikakhulu ilungele ipeleti yezixhobo zasemanzini. Tyibilika kumacala omabini.

Helilick roller rollell

I-roller iqokobhe yenye yeenxalenye eziphambili zokusebenza kwe-pellet yezigidi. Isetyenziselwe ukuqhubela phambili i-pellets ezahlukeneyo ze-biofuel, ukutya kwezilwanyana kunye nezinye iipelethi. Sebenzisa intsimbi ephezulu yokunganyangeki (i-40ccr, 20crmnti, i-GCR15), ukucinga ubushushu obushushu, ubunzima obufanayo. Ubomi benkonzo bude, kwaye kukho iintlobo ezahlukeneyo zezakhiwo ezifana ne-tooth-imile ivinjwe ivalwe, kwaye ivinjwe izinyo, kunye nomngxunya. Inxalenye ye-roller ye-roller yenziwa nge-shall yangaphakathi ye-eccentric kunye nezinye iindawo ezinemilinganiselo echanekileyo, elungele ukulungisa umgama phakathi kweemfuno zokuvelisa umsebenzisi, kwaye kulula ukulungisa i-roller ye-roller yeqokobhe.

Ukulumkela:

1. Ngokuchanekileyo khetha umlinganiso ofanelekileyo wokucinezelwa kweHie Hole;

2. Ngokuchanekileyo ihlengahlengise umsantsa ophakathi phakathi kwensingi kwaye uxinzelelo luphakathi lube phakathi kwe-0.1 kunye ne-0.3mm (i-roller yoxinzelelo iqhutywa emva kokuba i-granulator ivuliwe emva kokuba i-Granulator ivuliwe;

I-3. I-ring entsha ifa kufuneka isetyenziswe nge-roller yoxinzelelo entsha, kwaye uxinzelelo lroller kunye ne-roller kufuneka ikhululwe ngaphambili kwaye iqiniswe. Xa iikona ezibukhali zivela kumacala omabini e-roller, iflethi ye-roller yoxinzelelo kufuneka ibe yimgqomo yesandla ngexesha lokuqhubela phambili i-roller elungileyo kwaye i-fasa ifa;

I-4. Izinto ezingafunekiyo kufuneka ziphinde zicoceke ngokutsha ukucoca kunye nokwahlulahlula i-magnetic phambi kwepelletitizer ukunciphisa i-iron ecinezela ukuya kumngxunya wokufa. Kunye nokutshekisha umngxunya wokufa rhoqo ukuze ubone ukuba ikhona na ibhloko. Punch ngaphandle okanye uqhube ngaphandle umngxunya ovaliweyo ngexesha;

I-5. Ukuphuhliswa kweplastiki yomngxunya wengqengqelo yengqengqelo yekhonkco kufuneka kulungiswe. Xa ilungisa, kufuneka iqatshelwe ukuba eyona ndawo iphantsi yomphezulu wangaphakathi wokufa kwesandi kufuneka ibe yi-2mm ngaphezulu kwe-occentric groove roove roove roove roove roove roove roove;

I-6. I-roller ye-roller ye-roller yenziwa ngezinto ezinokunyangeka i-alting yeGolide ngokuPhakanyiswa kweGolide kunye nonyango lobushushu. Indlela yokungaphezulu kwamazinyo ye-roller ye-roller ineempembelelo ezithile kumsebenzi wokusebenza.

Iprofayile esetyenziswayo esetyenziswayo iprofayile ye-roller ye-roller

I-1. Dlula kunye neeRoove zamazinyo zisetyenziselwa ikakhulu ekuthatheni imfuyo kunye nempahla yeenkukhu. Inzuzo yokupasa i-rollers kukuba i-ring idle ngokulinganayo, kodwa ukusebenza kwekhoyini kulihlwempu.

2.Izinyo le-Groove Groove i-rooller iroller inomsebenzi ofanelekileyo wokusebenza kwaye isetyenziswa kwimithombo yobisi, kodwa ukunxibiswa kwe-farting ayifani. Izinyo le-Groove I-Groove i-Groove i-roller enomda otywinelweyo ikakhulu ilungele ipeleti yezixhobo zasemanzini. Tyibilika kumacala omabini.