Ingxenye 1: Ukuhlola ngaphambi kokufakwa

1. Indandatho yokufa ngaphambi kokufakwa

Ukuthi indawo yokusebenza ikhona.

Ukuthi ingabe i-groove igqokwa, nokuthi umgodi onontambo wephukile.

Noma ngabe i-Dialion Hole kanye ne-Compression ratio ilungile

Noma ngabe kukhona ama-dent noma amamaki okugqoka ku-hoop kanye ne-tapered ebusweni, njengoba kukhonjisiwe kuMfanekiso 1 no-2.

2. Ukuhlolwa kwe-roller ngaphambi kokufakwa

Ukuthi ukujikeleza kwengxenye kuyinto ejwayelekile

Ukuthi umngcele we-roller ugqokwa

Ukuthi ukwakheka kwamazinyo sekuqediwe

3. Bheka isimo sokugqoka se-hoop, bese ubeka esikhundleni sokungasebenzi kahle ngesikhathi

4. Hlola ukugqokwa kwendawo ekhuphukayo ye-drive rim, bese ubeka esikhundleni sokuhlulwa kwedrayivu ehlulekile ngesikhathi

5. Bheka futhi uguqule i-angle ye-scrace ukugwema ukusakazeka okungalingani kwezinto ezibonakalayo

6. Ukuthi umgodi wokufaka wesigaxa sokondliwa ulimele noma cha

Ingxenye 2: Izidingo zokufakwa kwendandatho yokufa

1. Qinisa wonke amantongomane nama-bolts ngokulinganayo ku-torque edingekayo

-Sz LH SSOX 1 70 (600 imodeli) njengesibonelo, indandatho yokufa ye-Torque ingu-30 0 N. M, Fengshang-Sz LH535 x1 90 granulator ebambe ibhokisi bolque actque 470n.m), iTorque Wrench OnjengeLwakhonjisiwe. Lapho isigaxa sendandatho sifa, ubuso bokugcina bokufa kwendandatho kufanele bugcinwe kungakapheli u-0,20 mm, njengoba kukhonjisiwe kuMfanekiso 4.

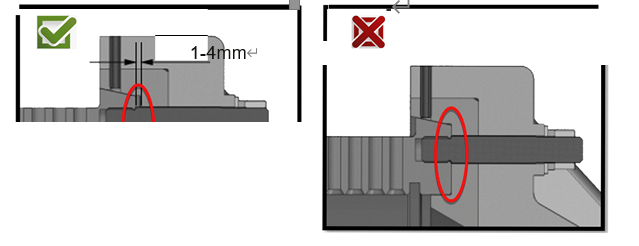

2. Lapho isigaxa sendandatho sifa, imvume phakathi kobuso bokuphela kwendandatho kufa kanye nobuso bokuphela kwe-drive wheel flange ngu-1-4mm, ngaphandle kwalokho ama-bolts asheshe aphulwe noma indandatho yokufa kungaphulwa.

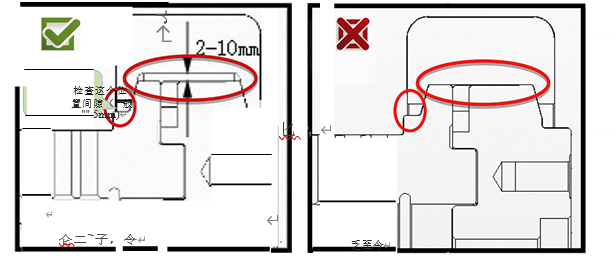

3. Lapho ufaka indandatho ye-hoop kufa, ukhiye wonke amantongomane nama-bolts ngokulinganayo ngokuya nge-torque edingekayo, futhi uqinisekise ukuthi izikhala phakathi kwebhokisi ngalinye eliphethe ziyalingana ngesikhathi senqubo yokukhiya. Sebenzisa igeji yomdabu ukukala igebe phakathi komhlaba elingaphakathi lebhokisi lokubamba kanye nendawo yangaphandle yendandatho yendandatho yokufa (imvamisa 2-10mm). Njengoba kukhonjisiwe kuMfanekiso 6, uma igebe lincane kakhulu noma alikho igebe, ibhokisi elibambekayo kufanele lithathelwe indawo.

I-4. Igebe lokufa elifakayo kufanele libe phakathi kuka-0.1-0.3 mm, futhi ukulungiswa kungenziwa ngokuhlolwa okubukwayo. Lapho indandatho ifa ijikeleza, kungcono ukuthi ukugoqa akuguquki. Lapho kusetshenziswa isifa esisha, ikakhulukazi lapho kufa indandatho enomgodi omncane wokufa, igebe lokufa livame ukukhuphuka ukuqedela isikhathi sokuqalisa nokugcina indandatho yendandatho yendandatho.

I-5. Ngemuva kokufa kwendandatho kufakiwe, hlola ukuthi i-roller icindezelwe yini

Ingxenye 3: Indandatho yokufa nokugcina

1. Indandatho yokufa kufanele igcinwe endaweni eyomile nehlanzekile futhi imakwe ngemininingwane.

2

3. Uma umgodi we-die wendandatho ushona uvinjelwe yizinto ezibonakalayo, sicela usebenzise indlela yokucwiliswa kawoyela noma ukupheka ukuthambisa impahla, bese uphinde ujikeleze.

4. Lapho indandatho yokufa igcinwa isikhathi esingaphezu kwezinyanga eziyisithupha, uwoyela ngaphakathi udinga ukugcwaliswa.

5 I-Fortravel Groove, futhi kusekhona isibonelelo sokulungiswa kwe-eccentric shaft ngemuva kokulungiswa.