Esikhathini sanamuhla, isidingo sokudla kwezilwane sesikhuphukile. Njengoba isidingo semikhiqizo yemfuyo sikhuphuka, ukudla okuphakelayo kudlala indima ebalulekile ekuhlangabezaneni nalezi zidingo. Kodwa-ke, ama-feed mills avame ukubhekana nenselelo yokulondolozwa nokulungisa izindandatho zifa, okuyingxenye ebalulekile yokukhiqiza ama-pellets akondla aphezulu.

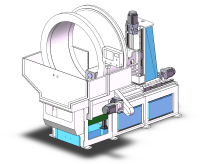

Ukuze uxazulule lezi zinkinga, isixazululo esinqenqemeni sesivele emshinini othomathikhi wokufa okuzenzakalelayo. Le divayisi entsha inikezela ukusebenza okuphelele okwenzelwe indandatho yokufa kwama-ring kuma-feed mill.

- Ukuhlanza izimbobo. Kungasusa ngempumelelo izinto ezisele endaweni yokufa kwendandatho. Ngokuhamba kwesikhathi, izindandatho zifa zingavalwa noma zivalwe, zivimbela inqubo yokukhiqiza. Ngomsebenzi wokuhlanza umgodi, umshini wokuphindaphinda ungasusa noma yikuphi ukungcola noma izithiyo ezindabeni zendandatho. Lokhu akugcini nje ngokukhulisa amanani okukhiqiza ama-pellet, kepha futhi kunciphisa ingozi yesikhathi sokuphumula ngenxa yokuvalwa njalo.

- Izimbobo zokuhlanza. Kuhle kakhulu emgodini wokuhlasela umgodi. Ukuhlanza inkemba yenqubo yokubushelela nokuhlanza umkhawulo womgodi wendandatho kufa. Lesi sici sandisa ukuqina okuphelele kanye nokuphila kwendandatho kufa, okwenza amandla okuphakelayo ama-Mills ukuze asindise ezindlekweni zokubuyiselwa kwemali ngokuhamba kwesikhathi.

- Ukugaya ingaphakathi lendandatho kufa. Lo mshini ungahle ugaye indawo yangaphakathi yendandatho iyafa. Ngokusebenzisa amasu okugaya aqondile, umshini ungalungisa noma yikuphi ukungahambi kahle komhlaba noma ukulimala kwendandatho kufa. Lokhu kuqinisekisa ama-pellets akhiqizwa ngokunemba okuphezulu kakhulu, ngcono ikhwalithi yokuphakelayo kanye nempilo yezilwane yonke.