Impilo yenkonzo yendandatho yokufa kwe-granulator izothintwa yizici eziningi, kufaka phakathi impahla yendandatho yokufa, izici zezinto zokukhiqiza, izindlela zokusebenza kanye nokunakekela, kunzima ukunikeza inani lempilo ngqo. Kodwa-ke, ngokulungiswa okunengqondo nokusetshenziswa, impilo yenkonzo yendandatho yokufa inganwetshwa ngempumelelo.

Impilo ejwayelekile yenkonzo ye-granulator ring.

- Ngokuvamile, impilo yenkonzo yendandatho yokufa kwe-granulator ingafinyelela amahora angama-1000 kuya kwayi-1400.

- Ngokunakekelwa okuhle nokunakekelwa, impilo yenhlangano yendandatho yokufa inganwetshwa.

Izici ezithinta impilo yendandatho kufa kwe-granulator

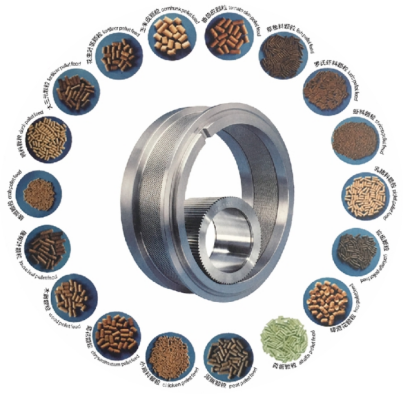

- ** Indwangu **: Izinto ezibonakalayo zokufa zinomthelela omkhulu kwisikhumbuzo sayo sokuphila. Isibonelo, indandatho yensimbi engenasici ivela ngokuvamile inempilo yenkonzo ende, ngenkathi indandatho yensimbi yekhabhoni yekhabhoni ifa linempilo emfushane yesevisi.

- ** Izinto zokukhiqiza **: Izinto ezahlukahlukene zinamazinga ahlukile wokugqoka endandatho afa. Izinto ezinobulukhuni obuphezulu noma okuqukethwe okuphezulu kwe-fiber kungasheshisa ukugqokwa kwendandatho kufa.

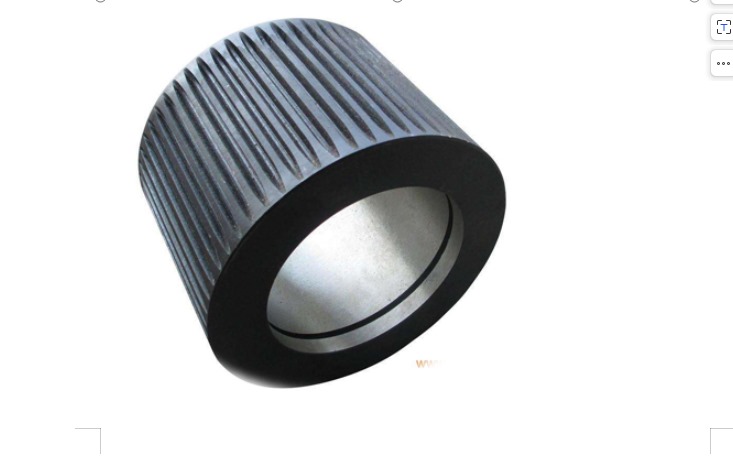

- ** Indlela yokusebenza **: Indlela efanelekile yokusebenza kanye nokunakekelwa kuyisihluthulelo sokwelula impilo yendandatho. Lokhu kufaka phakathi ukuhlanza indandatho kufa njalo, kugcina ukuthambisa okulungile, nokugwema ukulayisha ngokweqile.

Izindlela zokwelula impilo yendandatho yokufa kwe-granulator

- Khetha indandatho yokufa ngekhwalithi ephezulu futhi ilungele izidingo zokukhiqiza.

- Yenza ukusebenza kanye nokulungiswa ngokuqinile ngokuya ngezinqubo zokusebenza kanye nencwajana yokulungisa.

- Hlola njalo ukugqokwa kwendandatho kufa bese ubeka esikhundleni sendandatho egqoke kahle efa ngesikhathi esifanele.

- Sebenzisa amafutha okugcoba okufanele ukuze kugcinwe ukugcotshwa okuhle kwendandatho kufa.

Ngendlela engenhla, impilo yenkonzo yendandatho yokufa kwe-granulator inganwetshwa ngempumelelo, izindleko zokukhiqiza ingathuthukiswa, futhi ukusebenza kahle kokukhiqiza kungathuthukiswa.