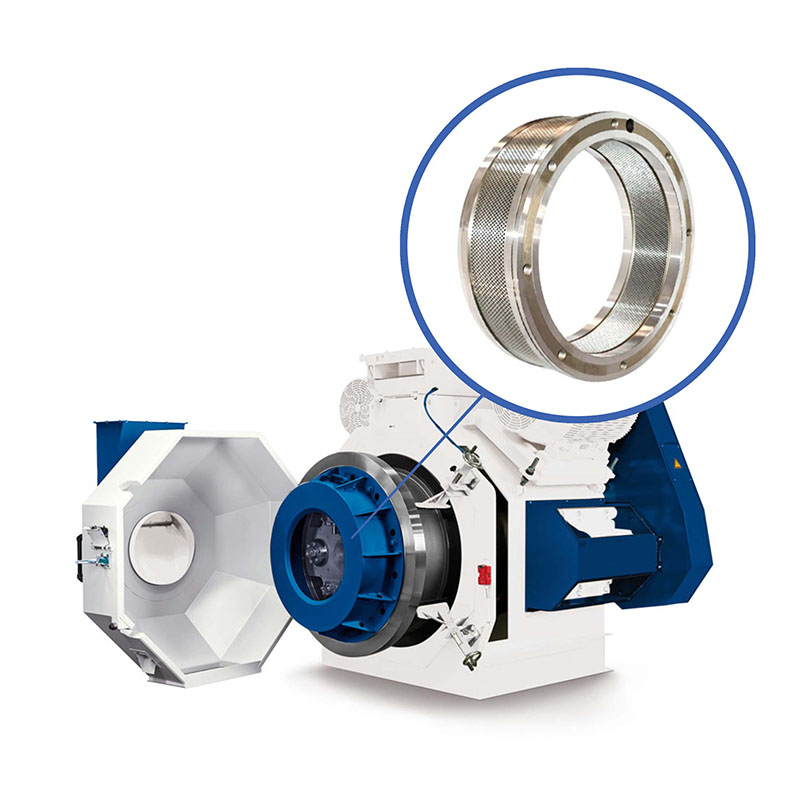

Umkhiqizi wendandatho ye-PTN Series Gezela izingxenye zePellet Mill Spare

- Shh.zhengengyi

● Indandatho ye-PTN Series iyafa

I-PTN Pellet Mill Series Ring DIE yenziwa ngensimbi ephezulu yensimbi noma i-chromium steel engenacala (German Standard x46cr13). Kucutshungulwa ngokuthethelela, ukusika, ukumba, ukwelashwa okushisa nezinye izinqubo. Ngokuphathwa okuqinile kokukhiqizwa kanye nohlelo lwekhwalithi, ubulukhuni, ubulukhuni be-die hole ukufana kanye nokuqedwa komgodi we-die kwendandatho yokukhiqiza kufile kakhulu.

Ipharameter

| S / N | Isifanekiso | UbungakoI-ID * i-ID * ububanzi obuphelele * Ububanzi be-Pad -MM | Usayizi womgodimm |

| 1 | I-PTN450 | 560 * 450 * 180 * 106 | 1-12 |

| 2 | I-PTN580 | I-680 * 580 * 216 * 140 | 1-12 |

| 3 | I-PTN650 | 791 * 650 * 245 * 175 | 1-12 |

Ukuhlaziywa kwesimo esingajwayelekile kanye nokuthuthuka okunconyiwe

Ukuhlaziywa kwesizathu sokuphukile (kuvame ukwenzeka ngaphakathi

Ukuphonswa okuqhubekayo kwamabhizinisi amancane)

1. Ukufa kwephulwe yi-drive wheel addion ebusweni

2. Ukufa kwephukile ngokugqoka nokuguqulwa kwendandatho yokufa kwe-die.

3. Ukufa okuphukile ngokulwa kokhiye wokushayela.

I-4. I-Indentation ihlatshwe umxhwele ebusweni bokufela ngomphumela obuthaka wedivayisi ye-de-ironing, bese kubangela ukufa ukuze kuqhekeke.

I-5. Ukuvulwa okuncane phakathi kokufa kanye ne-compression roller.

6. Ukufa kwephulwe isilinganiso esincane sokucindezela, okuphakelayo kwezinhlanzi ezincane kufa ngaphandle kwengcindezelo-

| Cha. | Ukubonakala | Izizathu | Isixazululo |

| 1 | Izinhlayiyana zokugoba, ngokuqhekeka |

| |

| 2 | Ngokuqhekeka kwe-transversal |

| |

| 3 | Imifantu emile mpo |

| |

| 4 | Imicibisholo ye-radiative | Izinhlayiya ezinkulu zikhona (uhhafu we-oorn noma ama-corns aphelele asele) | Lawula ukubusa kwezinto ezingavuthiwe, kwandise ukugaya ngisho nokugaya. |

| 5 | Ukungalingani kwemvelo |

| |

| 6. | Whisker njenge-pellet | Steam ngokweqile futhi ingcindezi enkulu kakhulu, imifantu ye-pellet lapho ishiye abafayo. | 1. Yehlisa ingcindezi ye-Steam, sebenzisa umusi wengcindezelo ephansi (15 - 20psi) ukuthola isimo. 2. Bheka isikhundla sokunciphisa i-valve. |