China OEM Twin Shaft Paddle Mixer - Feed industry BUHLER Series Ring Die for Pellet mill spare parts – Zhengyi

- SHH.ZHENGYI

China OEM Twin Shaft Paddle Mixer - Feed industry BUHLER Series Ring Die for Pellet mill spare parts – Zhengyi Detail:

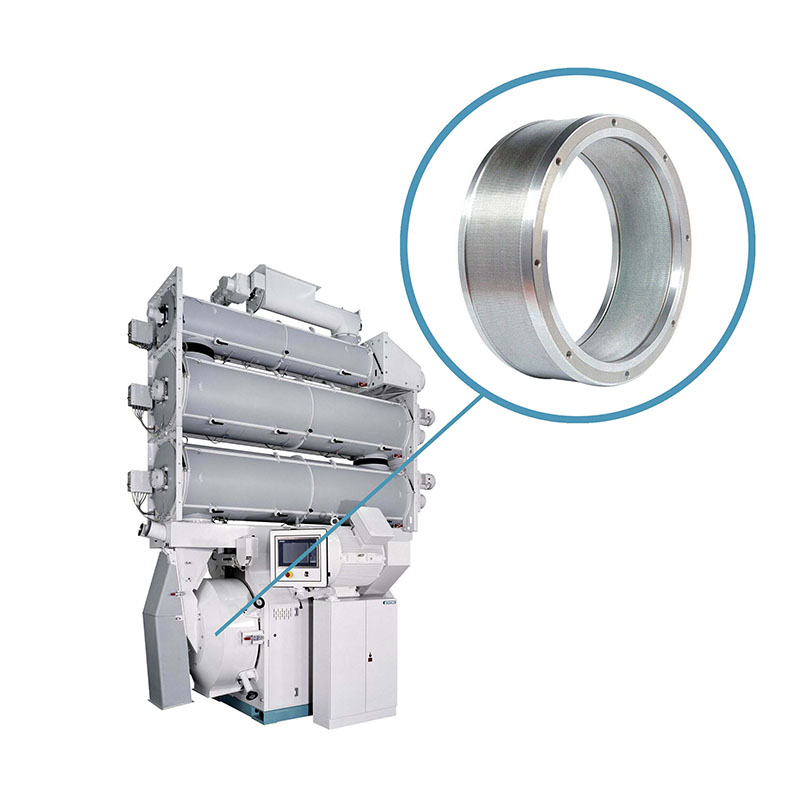

Zhengyi Ring Die of Spare Parts of Pellet mill

Using Euro Standard X46Cr13 and strictly production process control, the products with high precision have reached the first-class level of the industry in terms of assembly size and hole wall smoothness. The mature vacuum heat treatment process ensures the service life of the ring die products and brings customers a good experience in using the ring die.

We obtained a certificate of production for Ring Die and Roller shell in 2015

Advantage of Our Pellet Mill Ring Die

1. Select high-quality raw materials, secondary steelmaking, degassing billet.

2. Ring die material: X46Cr13 / 4Cr13 (stainless steel), 42Crmo / 20CrMnTi (alloy steel) or other custom materials.

3. Imported gun drill and multi-station drill, one-time forming die hole, high-quality finish, production of feed, beautiful appearance and high output.

4. Select the combination of vacuum furnace and continuous quenching furnace to ensure long service life.

5. According to the principle and requirements of the customer to design compression ratio and strength.

6. Microscopic examination to ensure product quality.

X46Cr13 / 4Cr13 stainless steel ring die processing technology:

● BUHLER series ring die

BUHLER pellet mill series ring die is made of high-quality alloy steel or high-chromium stainless steel (German standard X46cr13). It is processed by forging, cutting, drilling, heat treatment and other processes. Through strict production management and quality system, the hardness, die hole uniformity and die hole finish of the production ring die have reached very high quality.

Parameter

| S/N | Model | Size OD*ID*overall width*pad width -mm | Hole size mm |

| 1 | Buhler350 | 500*350*180*100 | 1-12 |

| 2 | Buhler400 | 558*400*200*120 | 1-12 |

| 3 | Buhler420*180 | 489*420*152*108 | 1-12 |

| 4 | Buhler420*138 | 489*420*182*138 | 1-12 |

| 5 | Buhler420*140 | 580*420*217*140 | 1-12 |

| 6 | Buhler520*138 | 610*520*182*138 | 1-12 |

| 7 | Buhler520*178 | 617*520*212*178 | 1-12 |

| 8 | Buhler660*178 | 799*660*236*178 | 1-12 |

| 9 | Buhler660*28 | 790*660*286*228 | 1-12 |

| 10 | Buhler660*265 | 790*660*324*265 | 1-12 |

Product detail pictures:

Related Product Guide:

We constantly function like a tangible group to ensure that we can give you the very best high-quality and also the very best cost for China OEM Twin Shaft Paddle Mixer - Feed industry BUHLER Series Ring Die for Pellet mill spare parts – Zhengyi , The product will supply to all over the world, such as: London , Philippines , Angola , Our items are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!