Professional manufacturer of Pellet

Industrial – use Ring Die Feed Pellet Mill Introduction

Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd. (CPSHZY) was established in 1997, it is the subsidiary of Mechanical & Electrical of Charoen Pokphand Group (CP M&E).

CPSHZY is specialized in manufacturing feed processing machineries and large-scale production of pellet mill dies over 25 years, as well as the provider of environmental protection system and solutions for feed plants and aquaculture farm. CPSHZY has obtained ISO9001 certification earlier and has a number of invention patents, as well as a high-tech enterprise in Shanghai.

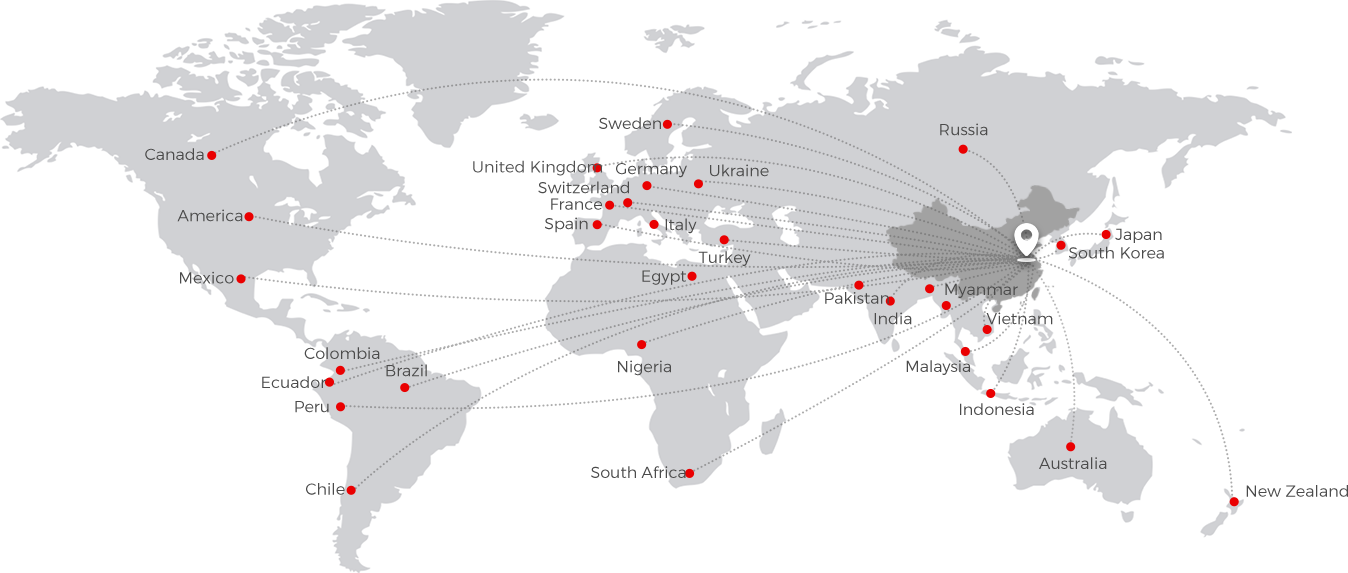

To provide complete projects with overall superiority for customers, CPSHZY organically combines of efficient equipment, technical know-how, professional and high-quality design and services in project management and varying specific conditions. CPSHZY feed machines and environmental protection system are exported to overseas like Southeast Asia, Middle east, Africa and Latin American.

Our company specializes in the production of large excavators.More than 95% of our products are exported to all parts of the world!

Get productThe products have been exported to over 40 countries and regions overseas.