1. Intelligence and automation: Ring mold granulators tend to integrate intelligent control systems, and improve the adaptability and production efficiency of the equipment by introducing technologies such as machine vision and automatic control algorithms. Intelligent control systems are expected to be the core driver for market development.

2. Environmental protection and sustainability: As the world pays more attention to environmental protection, environmentally friendly granulators will be more favored. This includes technological innovations such as using renewable energy to drive, optimizing energy efficiency and improving waste treatment capabilities.

3. Personalized customized services: The diverse needs of downstream industries prompt granulator manufacturers to provide more flexible solutions and services to meet specific process requirements and production needs in different fields.

4. International cooperation and market expansion: By strengthening technical exchanges, cooperative research and development and international market layout with other countries, Chinese ring die granulator companies will help enhance global competitiveness and share growth opportunities.

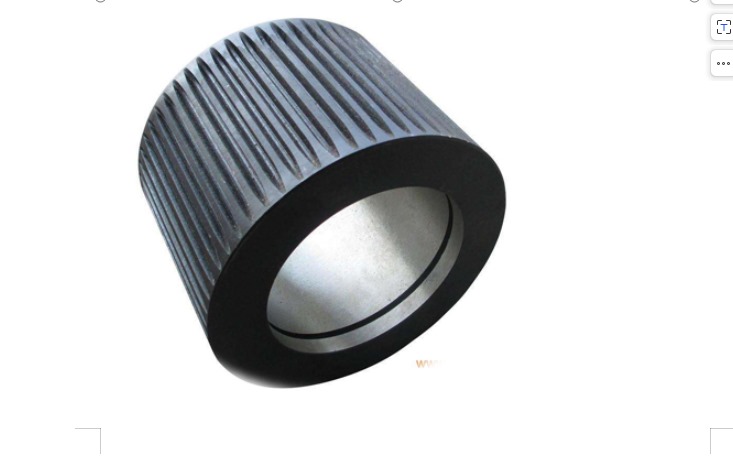

5. Technical transformation of high performance and durability: Through the advancement of material science and the application of precision manufacturing processes, the durability and molding quality of the new ring die pellet mill will be improved, meeting the differences in pellet fuel specifications and quality in different industries. needs.

6. Innovation of fixed structure: Changzhou Gude Machinery Co., Ltd.’s patent “A Fixed Structure of Ring Dies of Granulators” demonstrates the company’s innovation capabilities in the field of granulators. It optimizes the fixed structure of ring die to ensure that it can be used in multiple applications. Stability and durability of ring molds in industrial applications.

7. Variable frequency speed regulation and intelligent temperature control technology: The highly efficient and energy-saving ring-die pellet machine adopts variable frequency speed regulation and intelligent temperature control technology, which significantly reduces energy consumption and emissions during the production process, and improves the economic and environmental benefits of the enterprise. .

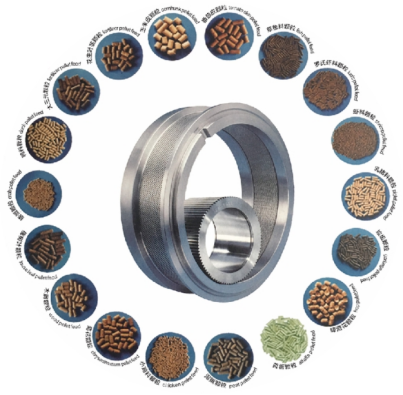

8. Versatility: The ring-die pellet machine is suitable for pelletizing different raw materials (wood chips, straw, rice husks, etc.), broadening the source of biomass energy and promoting the resource utilization of agricultural waste.

9. Optimize mold design and material selection: By optimizing mold design and material selection, the durability and molding quality of the ring die pellet machine will be improved.

These technological changes not only improve the performance and efficiency of the granulator, but also respond to the trend of environmental protection and sustainable development, meeting the market’s demand for efficient, environmentally friendly, and customized equipment.