Crushing roller shell is one of the main working parts of the pellet mill, and is widely used in the processing of various biofuel pellets, animal feed and other pellets.

During the working process of the granulator, in order to ensure that the raw material is pressed into the die hole, there must be a certain friction between the pressing roller and the material. Therefore, the pressing roller will be designed with different surface textures during production. At present, the most common types are corrugated open ended type, corrugated closed-ended type, dimpled type and so on.

Effect of Surface Texture of Press Roll Shell on Particle Quality:

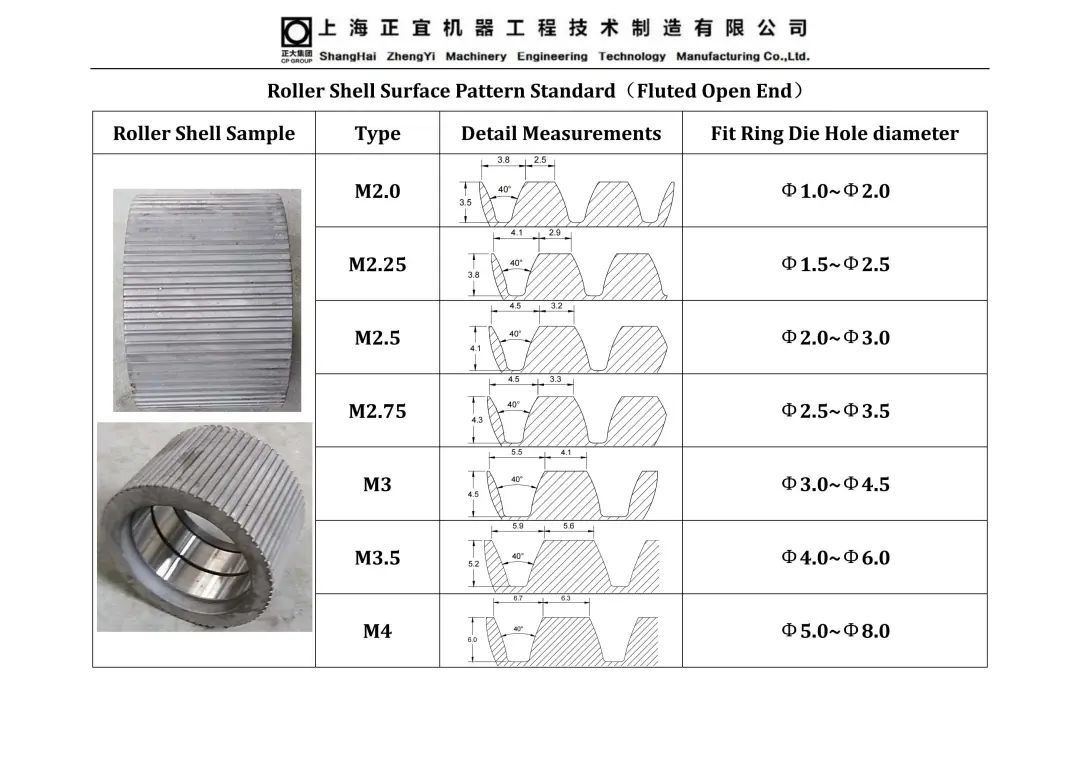

Corrugated open-ended type roller shell: good coil performance, widely used in livestock and poultry feed factories.

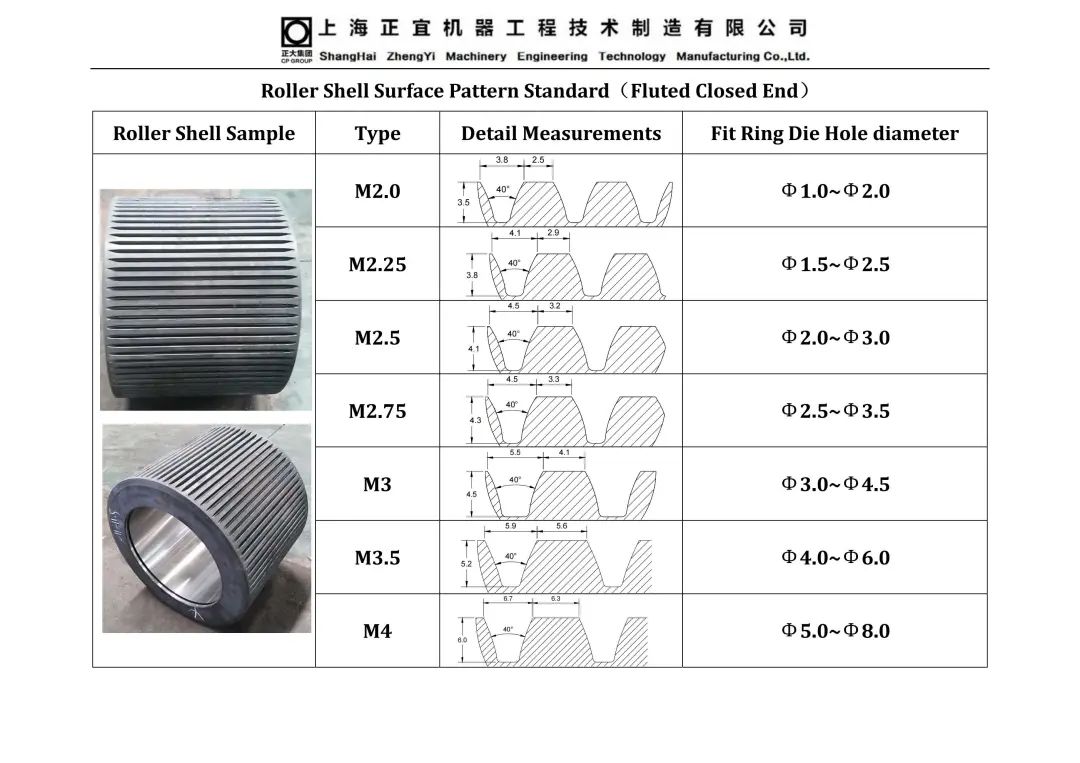

Corrugated closed-ended type roller shell: mainly suitable for the production of aquatic feeds.

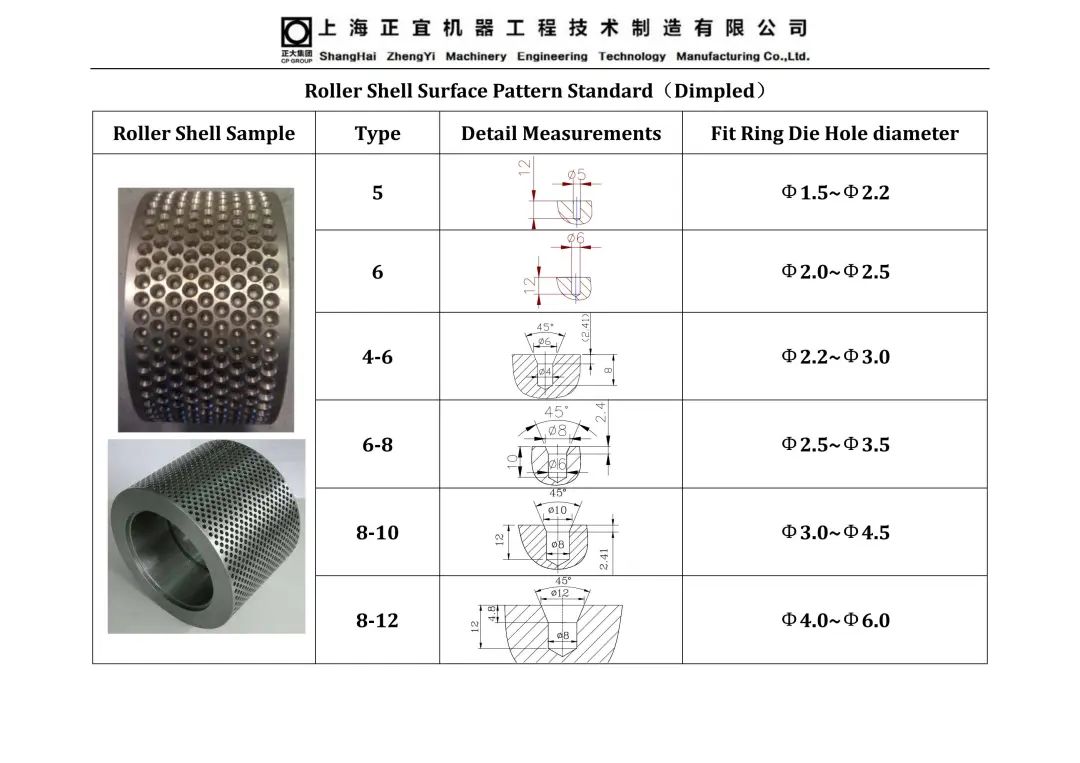

Dimple type roller shell: the advantage is that the ring die wears evenly.

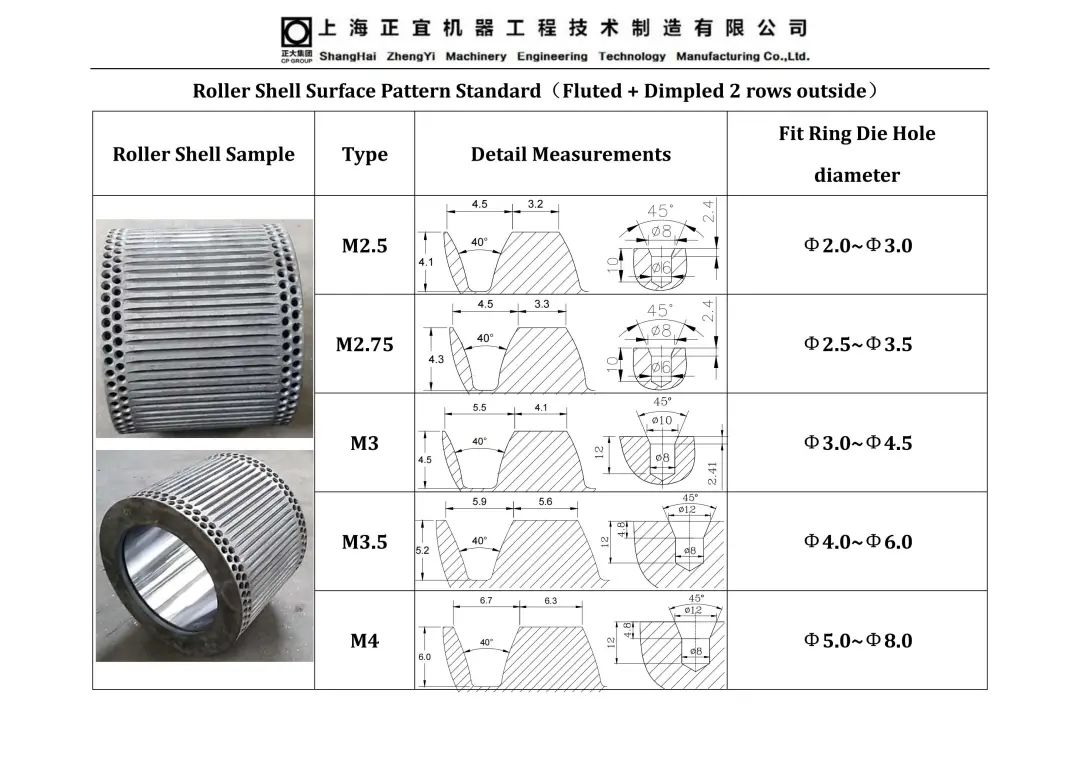

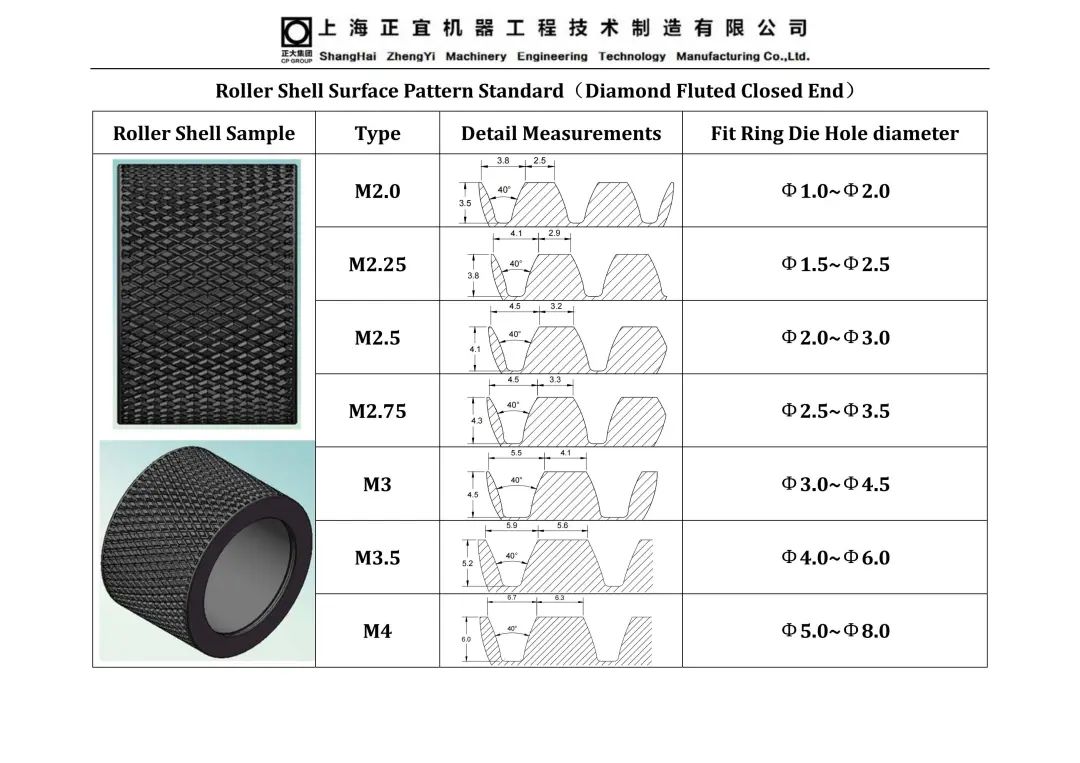

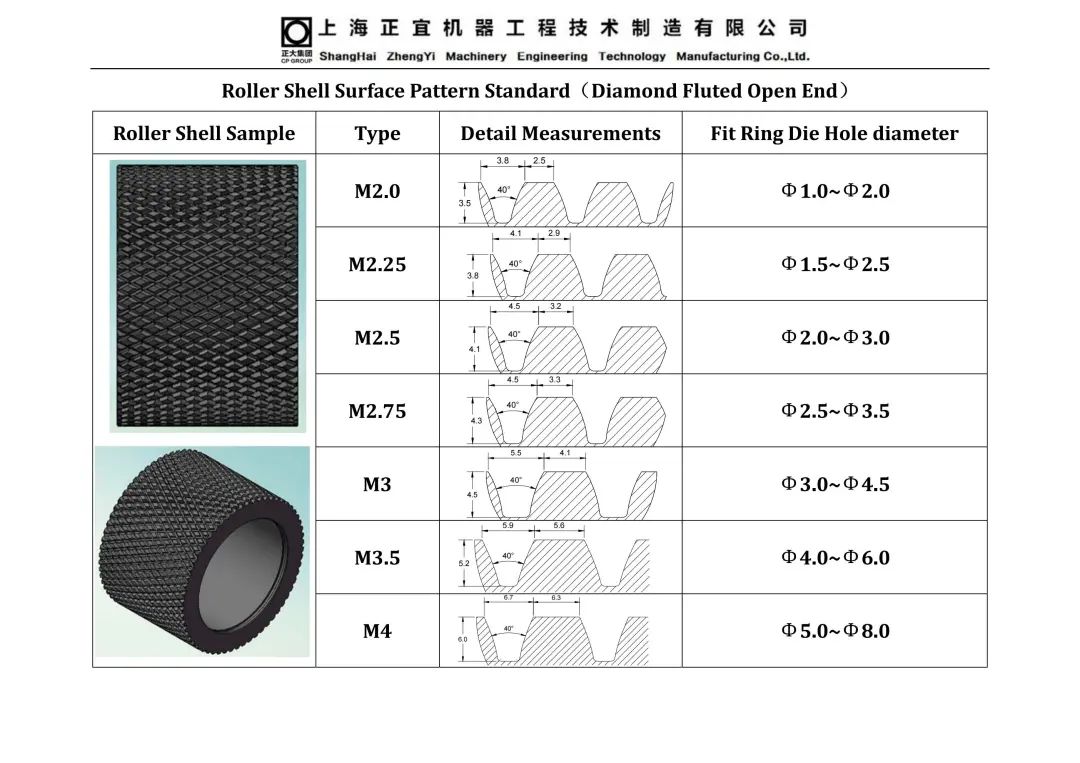

Shanghai Zhengyi Roller Shell Surface Type and Standard:

In order to facilitate customers to choose the most suitable surface for crushing roller shell, Shanghai Zhengyi has formulated the “Surface Texture Standard of the Roller Shell”, which specifies all the surface texture forms of Zhengyi’s roller shell products, as well as the range and size of each texture and its use and the aperture range of the ring die.

01

Corrugated Closed End

02

Corrugated Open End

03

Dimpled

04

Corrugated + Dimpled 2 rows outside

05

Diamond Fluted Closed End

06

Diamond Fluted Open End

Shanghai Zhengyi Machinery Engineering Technology Manufacturing Co., Ltd., established in 1997, is a manufacturer of feed machinery processing equipment and accessories with the feed industry as the main body, a provider of environmental protection solutions for feed plants and related environmental protection equipment, and a research and development manufacturer of microwave food equipment. Shanghai Zhengyi has set up many service outlets and offices overseas. It has obtained ISO9000 certification earlier, and has a number of invention patents. It is a high-tech enterprise in Shanghai.

Shanghai Zhengyi continues to innovate and develop in product research and development, and independently develops automatic intelligent ring mold repair machines, photobioreactors, microwave photo-oxygen deodorization equipment, sewage treatment equipment, and microwave food equipment. Shanghai Zhengyi’s ring die products cover nearly 200 specifications and models, and have more than 42,000 actual ring die design and production experience, involving raw materials such as livestock and poultry feed, cattle and sheep feed, aquatic product feed, and biomass wood pellets. The market enjoys a high reputation and a good reputation.