Renewable Design for Turnkey Feed Mill Project - Best price manufacturer of Closed tooth Roller Shell – Zhengyi

- SHH.ZHENGYI

Renewable Design for Turnkey Feed Mill Project - Best price manufacturer of Closed tooth Roller Shell – Zhengyi Detail:

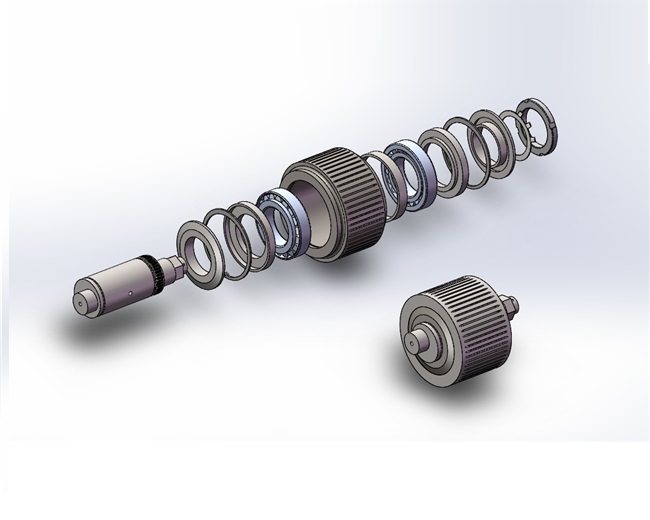

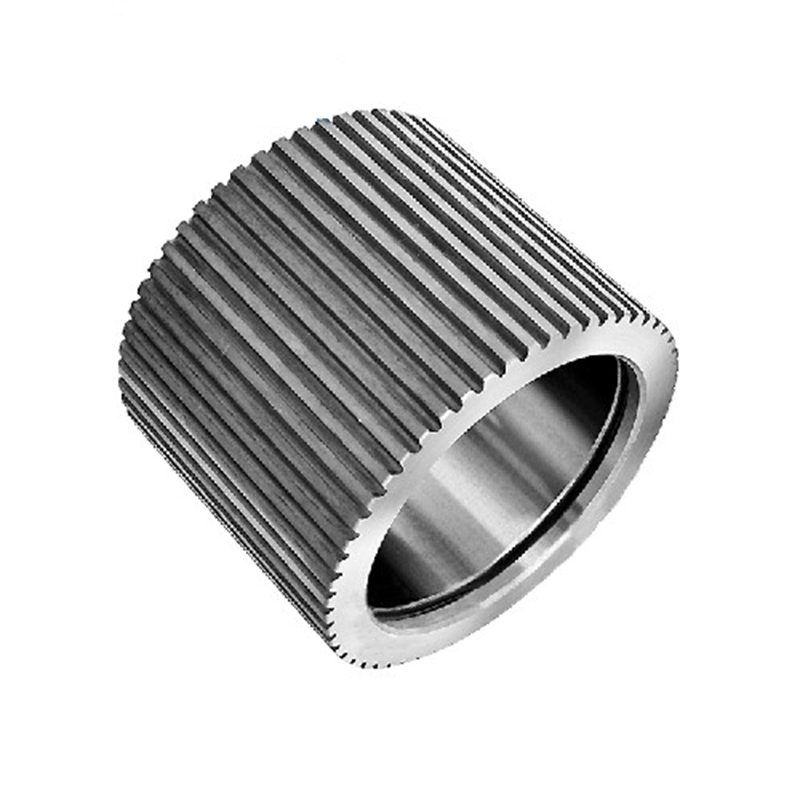

The roller shell is one of the main working parts of pellet mill. Used to process various biofuel pellets, animal feed and other pellets. Using high wear-resistant alloy steel (40Cr, 20Crmnti, Gcr15), carburizing heat treatment, uniform hardness. The service life is long, and there are different types of structures such as tooth-shaped through-shaped, tooth-shaped blocked, and hole-shaped. The pressing roller part is made of internal eccentric shaft and other parts with precise dimensions, which is convenient to adjust the distance between the pressing roller and the ring die according to the user’s production requirements, and it is easy to fold and install, and it is easy to replace the pressing roller shell.

The roller shell is one of the main working parts of pellet mill. Used to process various biofuel pellets, animal feed and other pellets. Using high wear-resistant alloy steel (40Cr, 20Crmnti, Gcr15), carburizing heat treatment, uniform hardness. The service life is long, and there are different types of structures such as tooth-shaped through-shaped, tooth-shaped blocked, and hole-shaped. The pressing roller part is made of internal eccentric shaft and other parts with precise dimensions, which is convenient to adjust the distance between the pressing roller and the ring die according to the user’s production requirements, and it is easy to fold and install, and it is easy to replace the pressing roller shell.

Precautions

1. Correctly select the appropriate die hole compression ratio.

2. Correctly adjust the working gap between the ring die and the pressure roller to be between 0.1 and 0.3mm (the pressure roller is driven by the ring die after the new granulator is turned on in a “like rotating but not rotating” state).

3. The new ring die should be used with a new pressure roller, and the pressure roller and the ring die must be loose before and then tightened. When sharp corners appear on both sides of the pressure roller, the flange of the pressure roller should be smoothed with a hand grinder in time to facilitate a good fit between the pressure roller and the ring die.

4. The raw material must undergo preliminary cleaning and magnetic separation before the pelletizer to reduce iron pressing into the die hole. And to check the die hole regularly to see if there is any blockage. Punch out or drill out the blocked mold hole in time.

5. Plastic deformation of the guide cone hole of the ring die should be repaired. When repairing, it should be noted that the lowest part of the working inner surface of the ring die should be 2mm higher than the bottom of the overtravel groove, and there is still room for adjusting the eccentric shaft of the pressure roller after repair Otherwise, the ring die should be scrapped.

6. The pressure roller shell is made of wear-resistant alloy material by gold processing and heat treatment. The tooth surface form of the pressure roller shell has a certain influence on the granulation performance.

Commonly used roller shell tooth profile: tooth profile through type, tooth profile not through type, hole type.

1. Pass and tooth groove rollers are mainly used for pelletizing livestock and poultry materials. The advantage of pass rollers is that the ring die wears evenly, but the coil performance is poor.

2. The tooth groove shape pressure roller has good coil material performance and is commonly used in feed factories, but the wear of the ring die is not uniform. The tooth groove shape pressure roller with sealing edge is mainly suitable for the pelletizing of aquatic materials. Slide on both sides.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Renewable Design for Turnkey Feed Mill Project - Best price manufacturer of Closed tooth Roller Shell – Zhengyi , The product will supply to all over the world, such as: Croatia , Japan , Mongolia , During the development, our company has built a well-known brand. It is well highly acclaimed by our customers. OEM and ODM are accepted. We are looking forward to customers from all over the world to join us to a wild cooperation.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.