Special Design for Pakenham Mill Animal Feed - Manufacturer of PTN Series Ring Die for Pellet mill spare parts – Zhengyi

- SHH.ZHENGYI

Special Design for Pakenham Mill Animal Feed - Manufacturer of PTN Series Ring Die for Pellet mill spare parts – Zhengyi Detail:

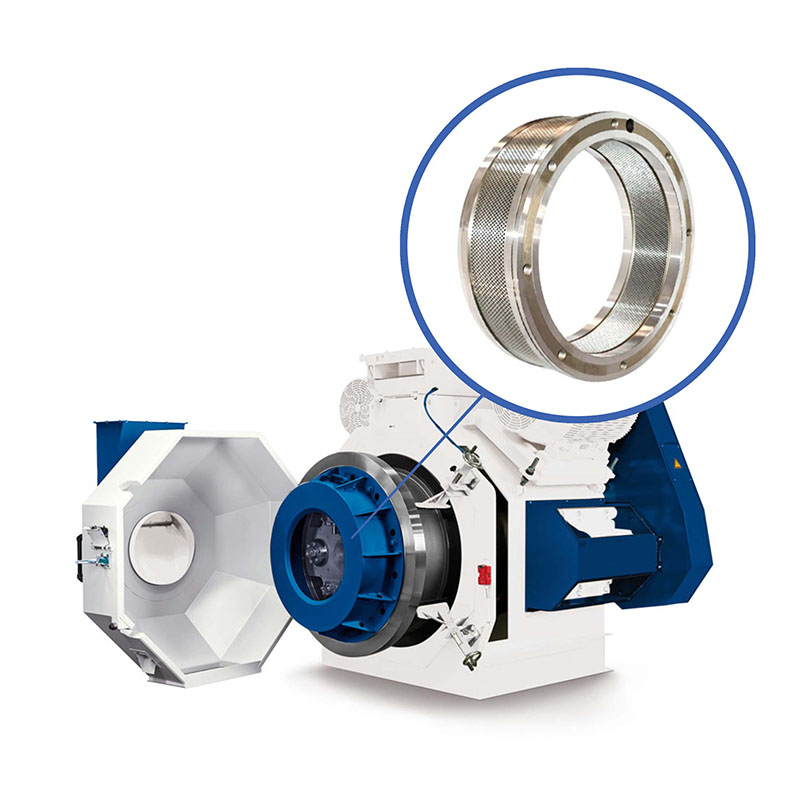

● PTN series ring die

PTN pellet mill series ring die is made of high-quality alloy steel or high-chromium stainless steel (German standard X46cr13). It is processed by forging, cutting, drilling, heat treatment and other processes. Through strict production management and quality system, the hardness, die hole uniformity and die hole finish of the production ring die have reached very high quality.

Parameter

| S/N | Model | Size OD*ID*overall width*pad width -mm | Hole size mm |

| 1 | PTN450 | 560*450*180*106 | 1-12 |

| 2 | PTN580 | 680*580*216*140 | 1-12 |

| 3 | PTN650 | 791*650*245*175 | 1-12 |

Analysis of Abnormal Situation and Recommended Improvements

Reason Analysis for Broken (normally occurred in

continuous casting of small enterprises)

1. Die broken by drive wheel matching surface

2. Die broken by wearing and deformation of die lining ring.

3. Die broken by waring of driving key.

4. Indentation impressed on the surface of the die for the weakening effect of the de-ironing device, and then cause die to crack.

5. Small opening between the die and the compression roller.

6. Die broken by small compression ratio, small diameter fish feed die without pressure-relief vent.

| No. | Appearance | Reasons | Solutions |

| 1 | Particle bends, with cracks |

|

|

| 2 | With transversal crack |

|

|

| 3 | Vertical cracks |

|

|

| 4 | Radiative cracks | Large particles exist (half an oorn or whole corns left) | Control the fineness of raw materials, increase grinding evenness. |

| 5 | Surface unevenness |

|

|

| 6. | Whisker like pellet | Too much steam and too large pressure, pellet cracks when left the die. | 1. Reduce steam pressure, use low-pressure steam (15 – 20psi)for conditioning. 2. Check the position of the reducing valve. |

Product detail pictures:

Related Product Guide:

We now have a highly efficient crew to deal with inquiries from clients. Our intention is 100% shopper pleasure by our merchandise quality, price tag & our staff service and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of Special Design for Pakenham Mill Animal Feed - Manufacturer of PTN Series Ring Die for Pellet mill spare parts – Zhengyi , The product will supply to all over the world, such as: Mozambique , Oman , Croatia , We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.